Let me narrate you a real story.

A ship was to arrive in a US port after a long sailing. Foam sample for fixed foam system was sent for testing at last port. Three days before arrival, the results of the foam sample analysis were received.

The test had failed. USCG did not allow the vessel to berth. The foam sample was redrawn and sent for analysis. Even though the sample passed, more than one day was lost in this process.

Question is, why did USCG not allow the ship to berth? They must have felt that it is really dangerous to allow the tanker to berth with an ineffective foam system.

Do we take our firefighting equipments and system this seriously? Let us admit it, we don’t !!!

The first step of showing the seriousness is knowing everything about our equipments.

In this article, I will discuss fixed fire fighting foam system on board ships.

Let us fire it out !!!

How foam extinguishes the fire

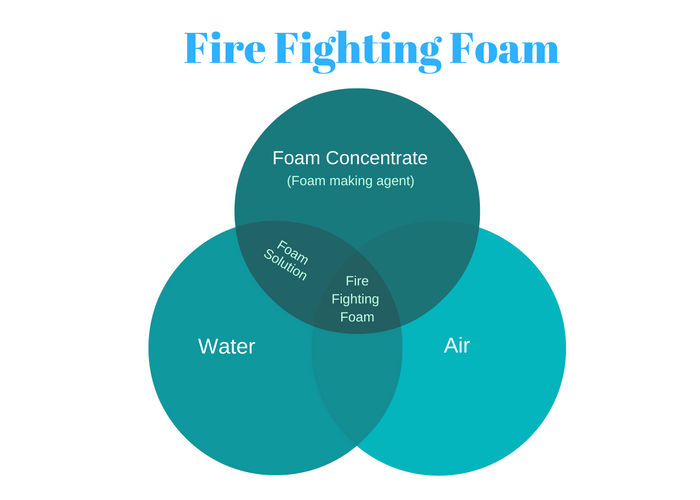

Fire fighting foam used on ships has three elements.

- Foam concentrate

- water

- air

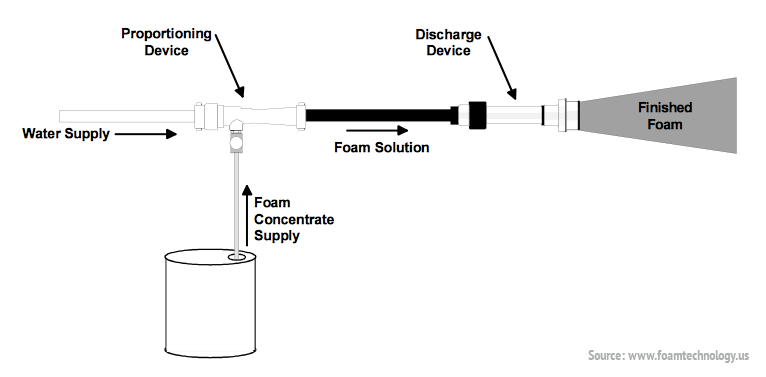

Foam concentrate is mixed with water in a correct proportion to form a foam solution. This foam solution when agitated with air produces foam.

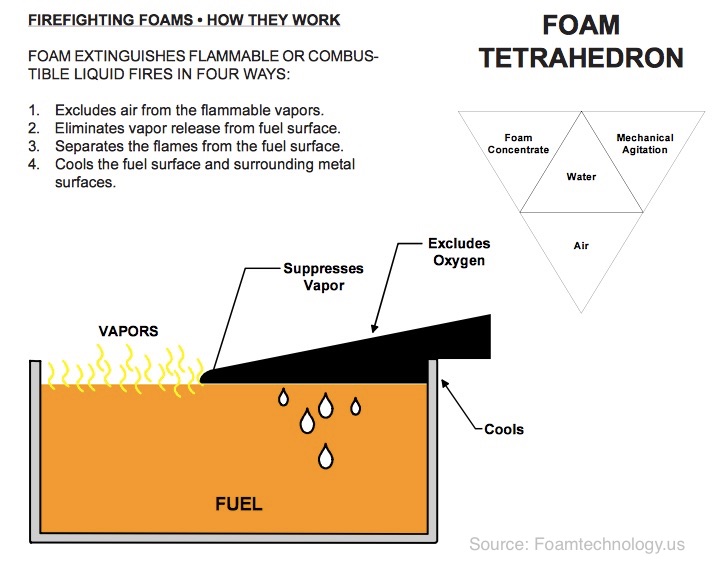

Foam extinguishes the fire in three ways

- It forms a blanket and thus removing the supply of oxygen to the fuel, the effect called smothering.

- The foam blanket does not allow the fuel vapors to generate, thus cutting the fuel supply to the fire

- Since foam has water, it cools the fuel surface

Main terms used in defining the foam

Now let us get to know few of the terms associated with foam.

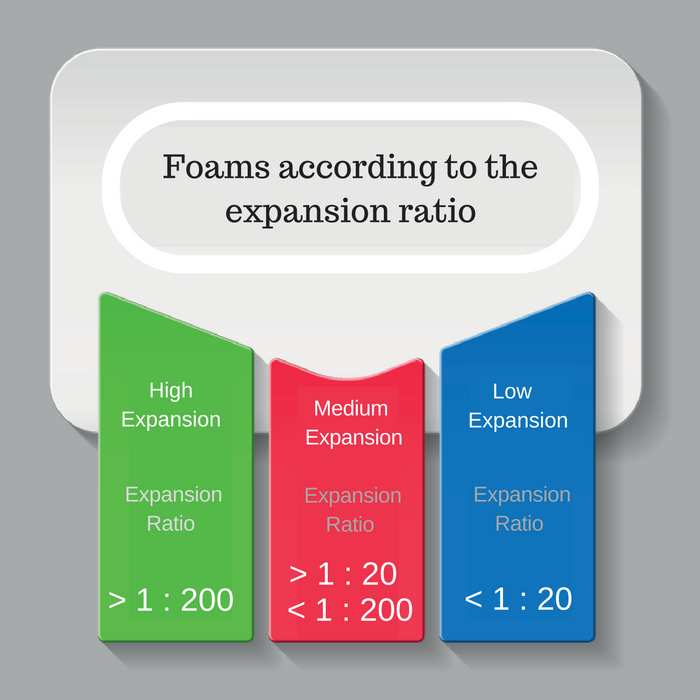

Expansion ratio

We all understand how a foam solution is formed. The form concentrate is mixed with the sea water and air at the foam monitor causes this foam solution to generate foam.

In other words, foam concentrate that we have in foam room tank expands to generate foam. Different foam concentrate has different capacity of how much foam these can generate from a fixed quantity of foam concentrate.

The ratio of the volume of foam generated (finished foam) to the foam concentrate used in that is called expansion ratio of the foam.

The foam with expansion ratio between 1:2 and 1:20 is called low expansion foam.

Foam with expansion ratio between 1:20 and 1:200 is called medium expansion foam.

Foam with expansion ratio above 1:200 is called high expansion foam.

Drainage time

Drainage time is the measure of how quickly a foam solution can move over a surface. Foam solution that has lesser drainage time move faster over a surface.

Drainage time is measured for 25% solution and 50% solution. This is called 25% drainage time and 50% drainage time.

Proportioning rate

Foam is generated by mixing foam concentrate with water. For the effective generation of foam that can be effective in firefighting, a correct amount of water need to be mixed with foam concentrate.

This ratio is called proportioning rate. It is also called mixing ratio or dilution rate.

So 6% foam concentrate means that the ideal foam solution from this foam needs to have 6 parts of the foam concentrate and 94 parts of water.

Knockdown speed and flow

Knockdown speed and flow is the ability of the foam to flow on the fuel and around the obstacles.

Good knockdown speed would mean that the foam is able to flow past the obstacles on the fuel surface.

Type of Foam solutions used on board ships

Broadly all foams fall under one of these two categories

- Chemical foam

- Mechanical foam

Chemical foam produces the foam by chemical reaction of two chemicals, one being alkali and second an acid.

Mechanical foam uses physical agitation of the foam concentrate to produce foam.

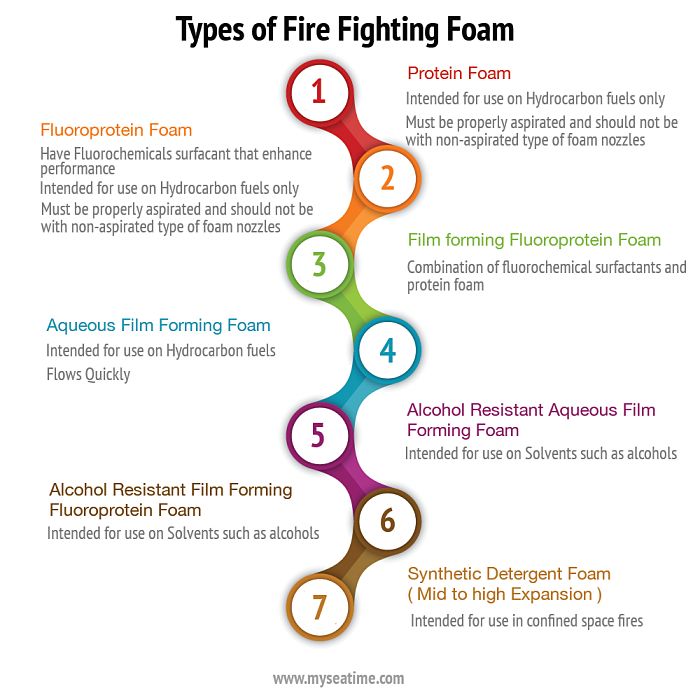

On board ships, the mechanical foam is mostly used. There are different types of mechanical foams used on board depending upon the expected source of the fire.

Let us discuss few of these.

Aqueous film forming foam concentrate (AFFF)

This is the very common type of foam used on board ship specially on tankers.

As the name suggests, apart from the foam bubbles, this foam makes an aqueous film over the surface that spreads across the surface of hydrocarbon to extinguish the fire.

These type of foam works on the fires generated from burning of hydrocarbons as it has a mixture of hydrocarbon and fluorinated surface active agents.

Alcohol resistant Aqueous film forming foam concentrate (AR-AFFF)

As I said foam has water in it. All the solvents like alcohols are miscible in water. So if we use normal foam on alcohol fires, alcohol will dissolve the water and foam will break up easily.

So for extinguishing the fires involving solvents like alcohol, normal foam concentrate will not do.

For fighting the fires involving alcohols and other solvents, Alcohol resistant foam is required.

On chemical tankers, that have foam as fixed fire fighting system for cargo fires, alcohol resistant foam is a must. This is because these ships carry alcohols (like Methanol, ethanol) as cargo.

So next time we check the foam certificate on a chemical tanker, we must look for the information mentioning the foam to be alcohol resistant.

Foams based upon the expansion ratio

We discussed that there are three types of foams based on the expansion ratio.

- High expansion foams

- Medium expansion foams

- Low expansion foams

But which foam will be used where ?

Would’t it be the fact that high expansion foams will generate more foam from less foam concentrate and thus be more effective ?

So the high expansion foam is very light and low expansion foam is comparatively heavier.

If we use high expansion foam for deck fires, the foam will fly with the wind and will not be able to extinguish the fire.

For this reason, for deck fires low expansion foam is used. On tankers, it will always be low expansion foam for fires of the cargo area.

High expansion foams are used for compartments such as holds and even machinery spaces where the space need to be filled with foam for fire fighting.

Functioning of Fixed foam system

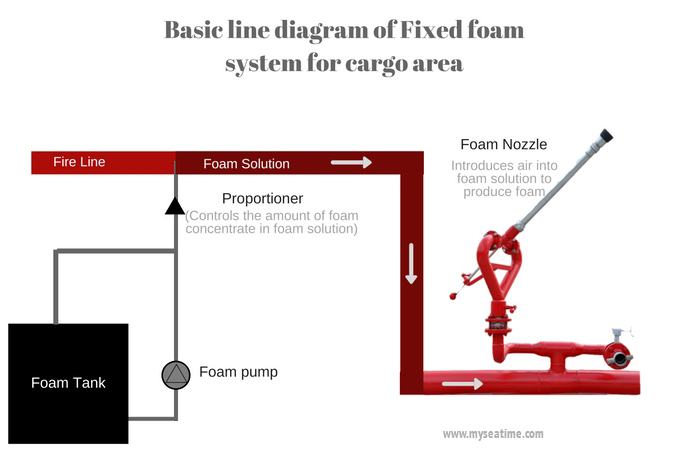

Below is the basic line diagram of a typical fixed foam system on ships.

The foam pump takes the foam concentrate from foam tank and injects it in desired ratio into the water. The proportioner controls the quantity of foam solution to inject.

The common type of proportioner is of ejector type. The more the fire line pressure, more foam it will inject. Ship staff are not supposed to touch the proportioner.

When the foam solution reaches foam nozzle on deck, the air is injected into the foam solution to create the fire fighting foam.

The foam so generated creates a layer over the fire and cuts the oxygen supply, the process called smothering to extinguish the fire.

Maintenance required on fixed foam system

There are many components of the fixed foam system such as

- Foam line

- Foam monitor

- Foam isolation valves

- Fire pumps

- foam concentrate (foam solution)

- Foam pump

- Foam proportioner

Each one of these need to work as desired. We, the ship staff need to make sure that each one of these are in perfect condition. The only way to ensure that is by testing of all the elements of the foam system.

i) Testing of foam line, foam monitor and foam isolation valves

If the foam line is leaking, or the foam monitors cannot be turn around to aim the foam at the fire, we would not be able to use the foam system.

Every year the foam line need to be pressure tested at least to the maximum working pressure. We must check the SMS manuals of the ship for any special testing requirements from the company.

The testing procedure would be

- Close all the valves of the fire line and foam line

- Open the foam monitor on the forward most part of the ship

- Start the fire pump at maximum pressure

- Slowly close the foam-monitor that was kept open

- Check for any leakage

Apart from checking the foam line leakage, we also need to check if any foam monitor valve is leaking. For this we just need to check that no foam monitor is leaking when the foam line is pressurised.

If we spot a leaking foam monitor, we must first check if the foam valve is tightly shut. If it is still leaking, we should overhaul the foam valve.

Remember, foam system is a critical equipment. And if we plan to remove the valve for overhaul, we must carry out risk assessment as for the period of the overhaul, the foam system would not be available for use. The company may also require the ship to take their approval before proceeding with this work.

We also need to test if the foam isolation valves are holding.

To test the foam isolation valves

- Keep the forward most foam monitor open

- Close the foam isolation valve one by one and check if the water from the foam monitor stops completely.

ii) Foam pump

We test the foam pump during the fire drill involving fire on deck. The foam pump is run on recirculation. We must make sure that the part of the foam line involved during re-circulation is effectively drained and empty after testing.

iii) Fire pump

Fire pump is an important part of the foam system. It delivers the foam solution to the foam monitors. While testing the fire pumps for foam system, we run the fire pump at full pressure.

We then open the two foam monitors and directs the jets overboard. The jets from these two should be able to cross each other.

iv) Foam concentrate

The main element from which the foam is generated is Foam concentrate stored in the foam tank. We have to check two things for foam concentrate

- Quantity of the foam concentrate

- Quality of the foam concentrate

For the vessels fitted with inert gas system, there need to sufficient foam concentrate for running for 20 minutes at maximum flow rate.

For vessels not fitted with inert gas system, there should be sufficent quanitity of foam concentrate for running for 30 minutes at maximum flow rate of the fire system.

The required quantity is usually marked on the foam tank gauge. We must ensure that this quantity is never below the mark.

With regard to quality of the foam, there is only one way we can know. By analysis of a sample of the foam.

Sample analysis of foam concentrate

SOLAS requires the foam sample to be tested after 3 years from the date it was placed onboard and there after every year.

Various tests are carried out on the foam sample to ensure that the foam is fit for the purpose it is supposed to do. The tests include

Sedimentation Test: Sediments should be less than 0.25%

pH value test: The pH of the foam concentrate should not be less than 6 and not more than 9.5 at 20 Deg C

Drainage time test

Chemical stability test for Alcohol resistant foam:

The alcohol resistant foams are different from other type of foams. Water content from normal foam will dissolve in the solvent and so these forms are not suitable for solvents. Additives in the alcohol resistant foam form a membrane that separates the solvent and foam which avoids the breaking up of the foam blanket.

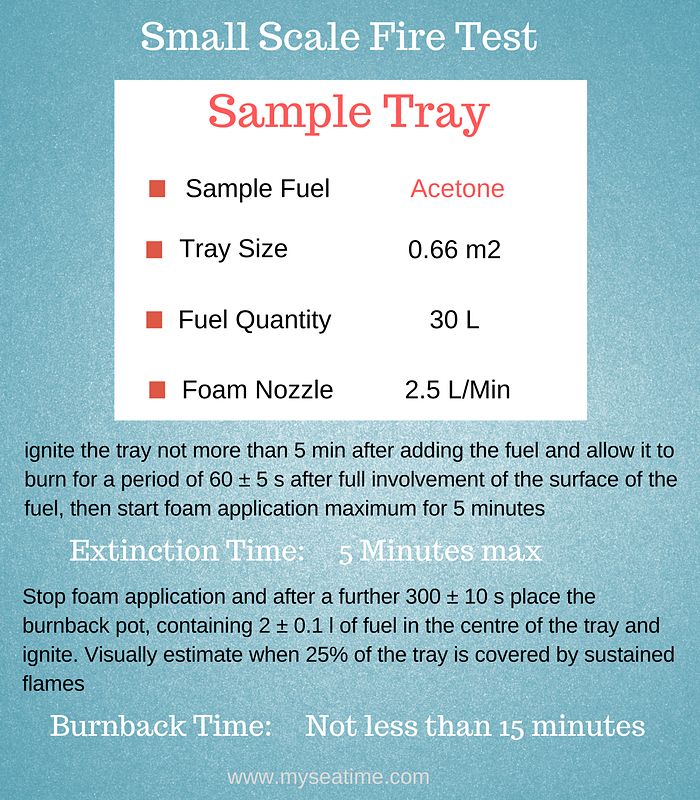

Small fire test:

In 2009, IMO revised the foam testing requirements on discovering that for protein based alcohol resistant Foam concentrate, even after all satisfactory test, with age it may not extinguish the fire as desired.

Following this discovery, a test called “Small scale fire test” is required for protein based foam concentrates.

In simple words this test is performed by actually extinguishing a sample of a small fire with the foam being tested.

The test is based upon testing or measuring of two parameters

- Extinction time

- Burn back time

Extinction time is the time taken for extinguishing the sample fire with the foam being tested. The extinction time should not be more than 5 minutes

Burn back time is the time in which the fire reignites if a sample of fire is place in the center of the foam.

Allowed Burn back time to cover 25% of the sample is 15 minutes.

v) Foam proportioner

Proportioner injects right quantity of the foam into the fire water to form foam solution. If the the proportioner is not set correctly, it either will inject more foam or less foam. In both cases, the system will be less effective.

If it injects more foam concentrate, the foam will not run for the time it is supposed to run. If it injects less foam concentrate, the foam generated may not be effective in extinguishing the fire.

SOLAS requires that foam proportioner must be tested by external agency once every five years.

The test is carried out to confirm that the proportioners are able to inject the foam concentrate in correct proportion.

The allowed variation from the designed value is +30% to -10%.

We should have the certificate for 5 yearly testing of Foam system on board.

Conclusion

Foam system is one of the main fire fighting system on board specially for deck fire on tankers.

It is important that the foam system is kept in a state of readiness at all times. For doing so, we must know how we are supposed to maintain these equipment and what tests we must perform.

Share this:

About Capt Rajeev Jassal

Capt. Rajeev Jassal has sailed for over 24 years mainly on crude oil, product and chemical tankers. He holds MBA in shipping & Logistics degree from London. He has done extensive research on quantitatively measuring Safety culture onboard and safety climate ashore which he believes is the most important element for safer shipping.

Search Blog

19 Comments

Sir, Myself Vetrivel E/O sailing in AET. Thank you so much for your valuable information in simple words. For the first time feels confident about Foam fire fighting system... Thank u once again sir..

DEAR CAPT RAJEEV, i am appearing for my phase 1 exams and your explanation is very handy . thanks alot. keep doing the good work . appreciate, if you could send me the links of your posts and also if u post something new to my email.

Thank you very much for your kindness to share your professional knowledge on the topics that you are discussing. I 've read some of your blogs, I find it very useful. May God bless you!

I have my exams. Can you please guide me with the proportion, Is it 1 part of foam in 20 parts of water or vice versa.

CO2 system on container vessels for cargo holds and engine room ??

Thank you, Sir. Well-explained and full of facts.

Very good article on the safety systems and foam concentrates. Degradation of the concentrate overtime is sometimes evident in ph fluctuations as well which is why it’s so important to test at least yearly.

Sir where can I find regarding 20mins if have inert gas and 30mins without inert gas

Nice Article!! ATLAS is an ISO 9001:2015 Certified Testing Laboratory duly certified by International Council for Machinery Lubrication – ICML Certified Level II Machinery Lubricant Analyst MLA II 002616. We are a state-of-the-art laboratory carrying out various tests for Lubricating Oils and Petroleum products. Over the years ATLAS Labs has provided a reliable platform in the field of testing and today is in the position to provide its analysis services to large national and international clients on a global scale.

Good day sir. Your article is so nice thank you Ma I know where to put the liquid foam for disposal or where to land it? Thanks in advance Hoping for your favorable response.

Thanks for having this article, it helps a lot. It’s a well-written blog and it is very informative. Keep on blogging, looking forward to see more of your posts! gas detector

Very very nice blog!! Hi there, I enjoy reading through your article post, I wanted to write a little comment to support you and wish you a good continuation, All the best for all your blogging efforts. IT Asset Disposal companies in India

short and sweet, the information about ships equipment always outspread and Confusing. but you collect them and share with everyone. thaks

Foamtech Antifire Company is India s Top Fire Extinguishing Manufacturers in India. We have a team of well-qualified engineers and technicians who are expert in their respective fields. These are available in different models and are offered in customized form as per the designs and specifications of our clients. Also, customers can avail these extinguishers at best price.

Excellent and very well explained, thank you

I have read a few of the articles on your website now, and I really like your style of blogging. I added it to my favorite’s web page list and will be checking back soon. Please check out my site as well and let me know what you think. Thanks. Fire fighting pumps

According to Value Market Research, the latest technology trends and global market opportunity analysis in the Fire Pump Market industry growing with a high CAGR in the upcoming year. Our report has categorized the market based on technology, service, development, vertical and region. https://www.valuemarketresearch.com/report/fire-pump-market

Very good article. Very well explained. Not more not less. Claps

Leave Comment

More things to do on myseatime

MySeaTime Blogs

Learn the difficult concepts of sailing described in a easy and story-telling way. These detailed and well researched articles provides value reading for all ranks.

Seafarers Question Answers

Ask or answer a question on this forum. Knowledge dies if it remains in our head. Share your knowledge by writing answers to the question

MySeaTime Podcast

This podcast on the maritime matters will provide value to the listeners. Short, crisp and full of value. Stay tuned for this section.

What is frequency of testing for alcohol resistant foam sample??I guess its annual compared to other protein foam??Also the AFFF used in portable extinguisher need to be tested at interval of 3 yeras??