A seafarer may not be involved in the ship construction so much. But that does not mean that they need not know anything about it. For example if you see a crack in ballast tank, you should be able to tell exactly where the crack is.

It is only possible if you can identify the structures inside the ballast tank. Same applies to the other parts of the ship too.

We read about ship construction during our competency exams. Only problem is ship construction topics starts from the medium level and not from the basic level.

For example if we need to draw the construction of double bottom, learning just involves placing each component at its place without answering why.

The first step of studying the ship construction need to be knowing about the basic terms of ship constructions.

In this post I will discuss and explain 10 basic terms used in ship construction.

But before we do that, first lets discuss briefly what ship is made of.

What are ships made of

Ships are made of steel and we all know that. But what all forms of steel are used in building ships. I mean what shape of steel ?

Before learning anything about ship construction we need to know the shapes used in ship construction. Let us discuss few of these.

Plate

We all know what we mean by plate. It is a rectangular shape steel with certain thickness. The most common place you can see the plate in ship construction is the main deck and side of the ship.

Bar

There is only one principle difference between steel plate and steel bar. The steel bar has lesser cross sectional width than the steel plate.

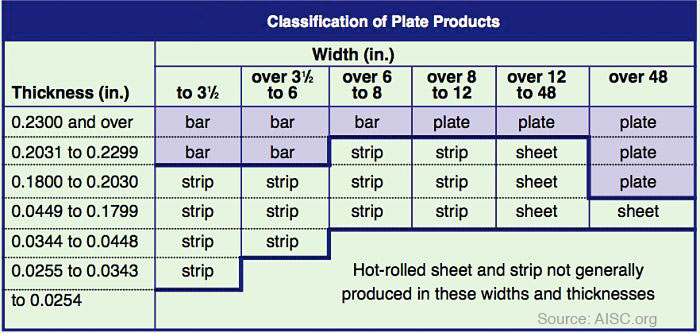

This table gives a fair idea what cross section of a steel can be called a plate/sheet or a bar.

Beam

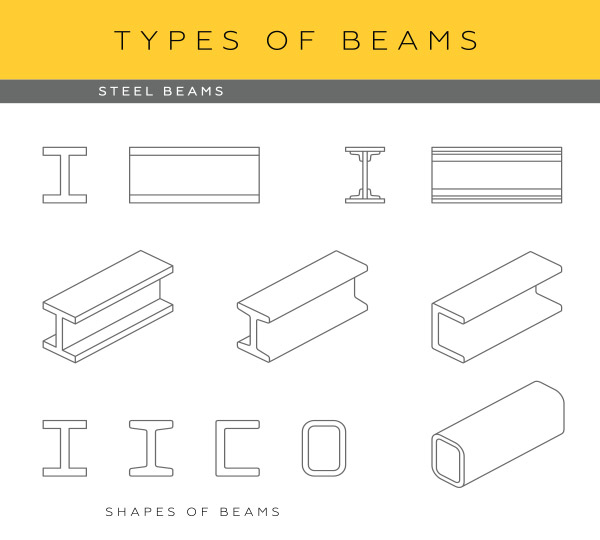

A beam is a structural element that increases load bearing capability and avoid bending of the structure. Beams can be categorized by many types but from point of ship construction, we need to categorize it through cross sectional shape.

For example, there are L-Shaped beams, C-shaped beams, I-shaped beams and SI-shaped beams. SI shaped beams are I-shaped beams with slight curved cross section.

Shape of the beams are not limited to these ones. It can be in many other shapes.

Now that we know the shapes and structure of the steel used in ship construction, we can discuss the ship construction terms. But we have to understand that all these structure will be a form of plate, bar or beam.

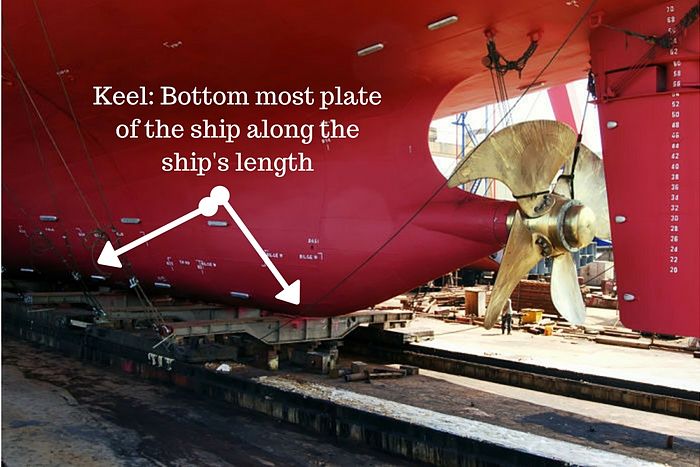

1. Keel

First thing first. When we say “Keel of the ship”, we are referring to a steel plate. Though it can also be in the form of steel bar but it is very rare these days.

Keel of the ship is the bottom most plate of the ship laid along the entire length of the ship.

During construction of the ship this is the first thing that is placed on the blocks. Because of this, laying the keep is considered to be the time when construction of the ship begins.

Keel laying also has the importance with respect to many IMO conventions as this is the date construction of the ship starts.

So keel is the steel plate with slightly more thickness than the other adjoining plates on its sides. This area need more strengthening because the ship sits on this area on the blocks, during construction as well as during dry docks.

We can consider the keel of the ship as the backbone or spine of the ship.

Years back keel laying involved actually laying the keel of the ship on the blocks. See below the keel of the titanic being laid.

Nowadays keel laying is considered to be the time when first piece of the ship structure is placed on the the wooden blocks. Like see below the keel laying of cruise ship “Anthem of the seas“.

2. Shell plating

Again when we say shell plating, we are referring to a steel plate. In this case it is too obvious from the name.

Shell plating is the steel plate used on the shell of the ship. The dictionary meaning of the shell is “hard outer covering”. So shell plating is whatever we see on outer side of the ship.

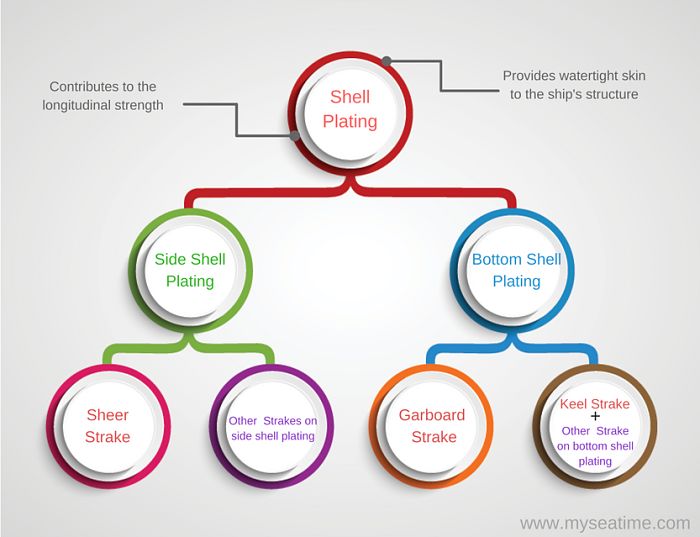

One of the main purpose of shell plating is to provide watertight skin of the ship. Apart from that it also adds to the longitudinal strength of the ship.

Ship construction requires us to be able to pin point each component. So when we say shell plating, it is a huge area. We can further divide this area in two broad parts, which is

- Bottom shell plating

- Side shell plating

I am so much sure that you already would know what these two terms mean.

Bottom shell plating is the shell plating on the bottom part of the ship. Or we can can that bottom shell plating form the watertight skin of the bottom of the ship. It is the plate laid in the horizontal direction.

To a certain extent we can say that even keel of the ship is also bottom shell plate.

Side shell plating is the shell plating on the sides of the ship that forms the watertight skin along the ship side. It is the plate laid in the vertical direction.

3. Deck plating

This is one is too obvious. Deck plating again is a plate. It is steel plate that forms the main deck of the ship.

As per the location, we can give a more specific name to the deck plating. For example accommodation deck plating or main deck plating.

4. Strake

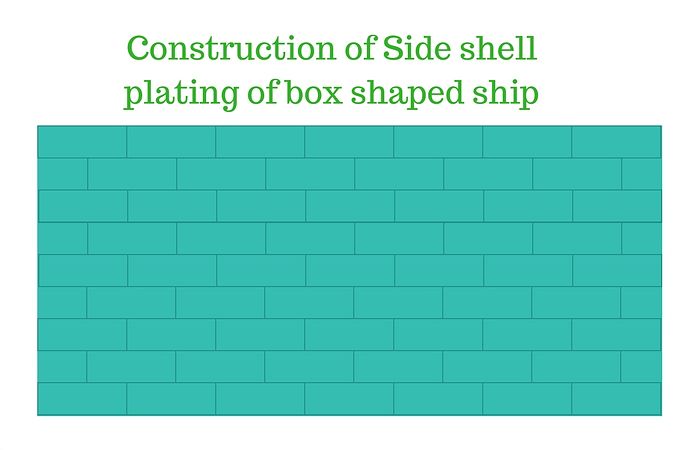

To understand what strake is, we need to again understand the construction of shell plating.

I am dead sure you know that ship’s side plate (Shell plating) is not made of single metal sheet. It is made of smaller sections of steel plates. These smaller sections of the plate are welded together.

In old days these were riveted instead of welding.

Irrespective of with what method these plates are joined together, these are placed in a certain pattern.

Let us understand this with an example of box shaped ship. The smaller plates that we are talking about would look something like this for the box shaped ship.

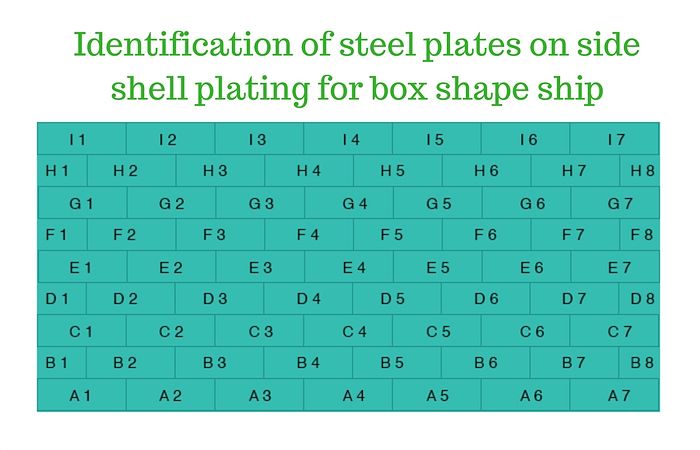

In naval architecture and ship construction each of these plate has an identification. These are numbered in certain pattern. For example the plates on the side shell plating are numbered like this.

- The plates are identified by a letter and a number

- Each plate is given a letter in the vertical direction starting with A from the bottom.

- Each plate is given a number in the horizontal direction starting from aft.

Now based on these numbering system the identification of plates for the box shaped ship would look something like this.

Each section of the plate placed in fore and aft direction is called a “strake”.

So in the above example, we have A-Strake, B-Strake and so on.

If we want to be more specific, We can say that we have starboard A-Strake , starboard B-strake and so on. Similar naming will be on the port side.

For the bottom shell plating, similar numbering is done for the plates forming it. For the bottom shell plating

- Plates are given a letter starting with “A” to the plate adjacent to the keel plate.

- Plates and given a number starting from the aft

So the plate adjacent to the keel plate will have a identification of A1, A2 and so on starting with A1 from the after most plate.

Now there are three type of strakes that you would hear in ship construction. Let us see what these are.

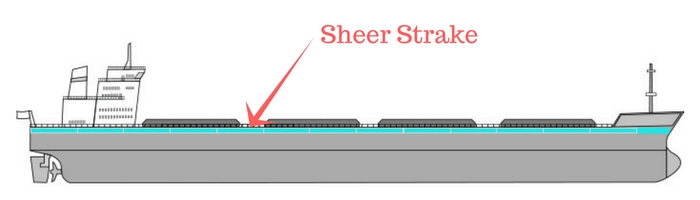

Shear Strake

Shear strake is the top most strake of the Side shell plating. So if side shell plating has strakes from A to K, then K-strake is the shear strake. This is the strake that connects with the deck plating.

Can you identify the shear strake in the box shape ship example that i gave above ? Yes, you got it right. I-Strake is the shear strake in this case.

Shear strake is usually of higher thickness and strength than other strakes. This is because this strake can have lot of physical damages during the life of ship.

Keel Strake

I earlier said that keel is a plate that is back bone of the ship. But keel plate is also made up of smaller sections of the steel plates. These strake of plates that form the keel of the ship is called Keel Strake.

The plates in the keel strake are number from aft to forward starting from the aft one which has the number “1”.

Unlike other strakes, keel strakes do not have letter associated with its naming.

Garboard Strake

Garboard strake is the first strake on each side of the keel strake. As we discussed in the bottom strakes, the first stake from the keel is named A-strake.

So we can also say that Bottom A-strake is called Garboard strake.

Now for the box shape ship, the naming of strakes might look simple but for actual ship with curved sides and flared bottom, it might not be that simple.

The naming and construction of side and bottom shell plating is provided in the “Shell expansion plan”.

Next time you get your hands on a shell expansion plan of your ship, try to read it to identify shear strake, keel strake and garboard strake.

So below picture shows how shell plating and Strakes are connected with each other.

5. Stiffners

A steel plate of 2mm thickness can be easily bent. If you lift this plate with the crane from its ends, it will most likely bend at the center. Now what can you do to avoid it from bending ?

One easy solution is to increase the thickness of the plate by welding two or more plates together. But in ship construction this is not a good idea. One among many reasons for this is that we do not want to increase the light weight of the ship.

The better option is to weld two of more flat bars either in fore and aft direction or athwartship direction.

In this case these flat bars will be called stiffners. Anything that is used solely to provide strength to a ship structure can be called a stiffner.

A stiffner welded in longitudinal direction is called “Longitudinal stiffner”. Same way a stiffners welded in transverse direction is simply called “transverse stiffner”.

Longitudinal stiffners and transverse stiffners can further will named according to various factors including the amount of strength these provide to the structure.

Let us discuss few of these.

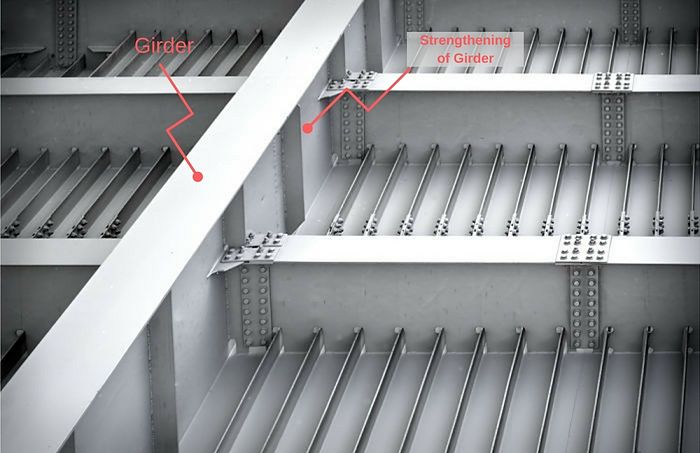

6. Girder

Girders are one form of longitudinal stiffners. These are

- Big size steel plate (or sometimes beams) connected to bottom of the ship

- Runs in fore and aft direction

- strengthen the ship against bending moment

Girders are also named according to its location. The girder at the center of the ship is called center girder.

In double bottom tanks, the thick solid metal plate that divides the ballast tanks into port and starboard tank is the center girder.

Apart from the center girder, there can be few girders on each side of the ship or double bottom.

Depending upon the breadth of the ship, there can be more than one side girder on each side.

While center girder runs in full depth of the double bottom tank, side girders may or may not run in full depth.

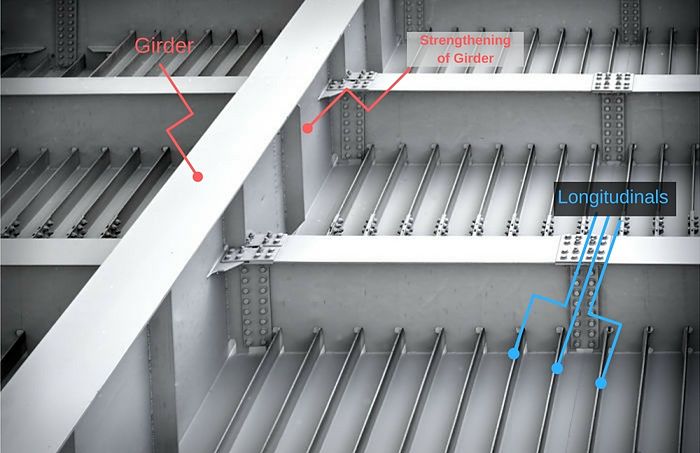

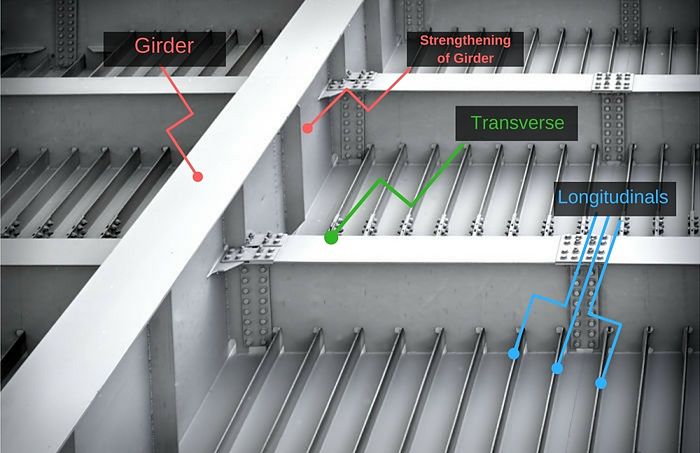

Though below photo is not that of a ship, it is good representation of a ship’s strengthening components. If you see in this case girder is further strengthened with something we may call “Vertical Stiffners” as there is no other specific name for it.

7. Longitudinals

Longitudinal is short name for longitudinal stiffners.

In most cases the longitudinals are beams (mostly L-beams) and runs along the length of the ship. Double bottom space is the most common space where you can easliy identify longitudinals.

Longitudinals are further named depending upon what section these longitudinals are strengthening.

In double bottom ballast tank, longitudinals strengthening the bottom are called “bottom longitudinals”. Longitudinals strenghtening the top of the ballast tank are called “top longitudinals”.

If you have been to a double bottom tank, these longitudinals are difficult to miss. The bottom longitudinals are the one we sometime step on to avoid stepping in the left over water (or mud) of the ballast tank.

I am sure you can locate the longitudinals in above picture that I shared. If you cannot, I share it again with marking of longitudinals.

8. Frames

Frames act as major transverse stiffners. Frames are

- Big size steel plate connected to bottom of the ship

- Runs in athwartship direction

- strengthen the ship against buckling and bending.

We can consider the frames to be similar to the girders but with only one difference. Frames runs in transverse (Athwartship) direction.

If keel is the backbone of the ship, the frames are considered to be the rib cage.

Frames are numbered starting from aft perpendiculars.

9. Transverse

Transverse is the short name for “transverse stiffners”. These are different from frames in two ways. First unlike frames these do not extend to full height of the compartment. Second transverse are of lesser strength and thickness than frames.

Based on the location of transverse, these may be called “bottom transverse”, “inner bottom transverse” or even “deck transverse”.

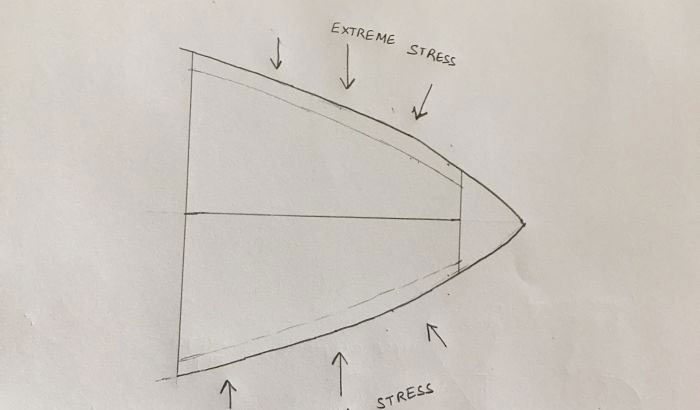

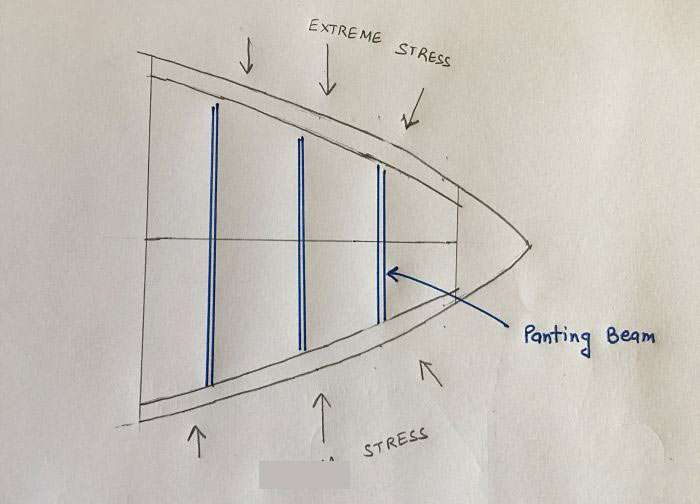

10. Stringers

In the above photo, notice how the girder is stiffned. The stiffner is welded in vertical direction. If same stiffner is required to be welded in horizontal direction, it will be called stringer.

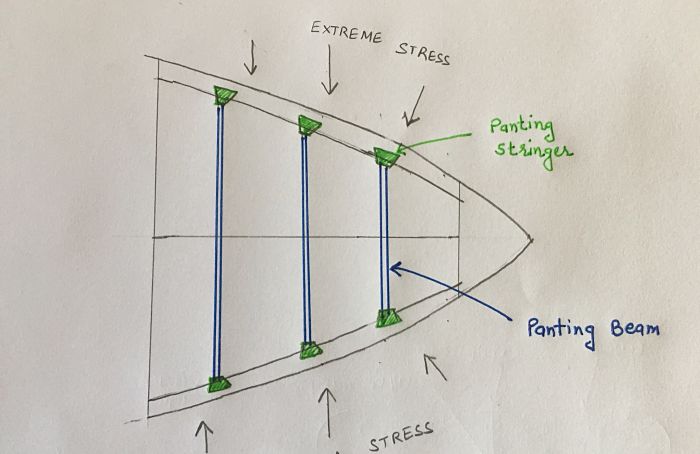

One of the location where stringer is mostly used is the forward part of the ship. Bow of the ship has to bear lots of stress and so requires extra strengthening.

I will limit myself with discussion of bow construction just to understand stringers. I will cover bow construction in detail some other day.

So among many other strengthening members, panting beams are used in this area to counter these stresses.

But even these beams need to be stiffened at the point where these connects with the side frame. Panting stringers does this job. As I said stringers are horizontal stiffeners (parallel to the water line).

Conclusion

Ship construction is something that requires a lot of imagination to understand. But even if someone has a strong imagination bone in the body, knowledge of ship construction will still be difficult without knowing basic terms used in it.

These 10 terms are the basic of ship constructions and once we know these, ship construction will be a little easier task.

Share this:

About Capt Rajeev Jassal

Capt. Rajeev Jassal has sailed for over 24 years mainly on crude oil, product and chemical tankers. He holds MBA in shipping & Logistics degree from London. He has done extensive research on quantitatively measuring Safety culture onboard and safety climate ashore which he believes is the most important element for safer shipping.

Search Blog

111 Comments

Very good article..... Also try this one on the web.. http://www.libramar.net/news/dnv_hull_structure_course/2015-02-25-2134.......It's about hull structure, It's very good...

First of all l take this oppertunity to appreciate you, for your efffort taken to post this very usefull Blog. This blog is very usefull to everyone in shipping field..

Thank you Gopalakrishnan..

Thanks a ton sir.Blogs are immensely helpful.

Glad you found it helpful Abhishek..

Sir,first of all i would like to thank you for the blogs,these are so simply written so that everyone can understand,quite helpful also to understand the basics.If you can write something about MS Act 1958,it can be more helpful.

Thanks Soumen. Sure I will consider writing on MS act. Meanwhile if you have any particular question, you can ask on our new section "Questions".

wonderful explanation sir

Glad you liked it Rahul..

I have been going through your blog from quite sometime now.They are really helpful! Thank you :)

Thanks, Aman...

really helpful,many thanks

Thanks for reading Mokrane...

this is very educational for me...

Glad to know that Ramon...

really good article easy to understand.

Thank you Vignesh...

Informative article, easy to understand, thanks

Glad you liked it Ridwan...

Ur explanation is very helpful with supportive pictures. Even as a senior ranked engineer I felt ur article was much helpful. Thank u. Keep it up & would like to read more of ur article.

Glad to hear that Arunava...

Sir, really thankful to you making such a clear and good explanation of ships construction, it was well labeled and very simple words used in explanation, and the image ugh too good. Thanks.

Glad you liked it Ayush...

Hello Sir , Was going through the page and was confused about the part " identification of plates for the box shaped ship would look something like this" if i am not mistaken you were trying to explain about the shell expansion plan in here right. the Alphabet I would not be there if i am not wrong, and can you please throw some light on shell expansion plan further. Wanted to know if thickness of side shell platings will be mentioned in the Shell Expansion plan.

Yes, Thickness is mentioned in shell expansion plan. I will cover this topic in one of my future blogs.

Btw great blog sir !!! Thanks for the detailed info :)

Glad you liked it Satya...

Very good basic explaination

Thanks....

Thanks a lot for your all efforts making all topics so easy to understand

Thanks Ercan...

Thanks for the add Thank for the information

Thanks Mohamed...

Due to this now i have understood most of the things..you have make it so simple to understand us...becoz of ur vast and deep experience..thank u for sharing..expecting more..rightnow m preaparing for class4

Glad you found it useful Krunal...

Sir your explanation is very good .Please provide more information about ship construction..

Glad you liked it Mukesh. I will cover more topics on ship construction in future...

Sir really thank you for this information. Looking forward to your other work about this field.

Thanks Carlo...

Very nicely explained.... Ship construction is really tough topic for us.....as u rightly said, it is started mid level rather from basics Thanks for clearing some basics....really helpful article

Thanks Amit...

This article is like braille for blinds. Simple and powerful

Thanks Aditya....

Very helpful thank you so much sir for these information helped me in preparation for the 2nd mate orals.

Glad you found it useful Sameer....

Good day, Mr Rajeev am very greatful for your articles, it really improve me a little, because am preparing for my oow examination in Nigeria maritime academy. please sir I still need more knowledge of ship construction from you am going for engineering. thanks Pius Anthony

Glad you found it useful Pius...

Thank you for your good explanation of those basic ship construction terms. I have some questions to ask sir. What are the structural members of the ship that counters yawning.heaving. swaying.surging. rolling and pitching. Thanks

Thanks alot sir, very good explanation.

capt what a incredible way you adopted to explain these terms..I am really impressed..thanks for sharing your precious knowledge

Main deck plating, where more strengthning?

your articles are really awesome...even after studying different book can't clear doubts, but yours are so understandable....thanks again sir...

Thank you so much rajeev sir, REALLY you have explained these 10 terms very well. Thank you

Dear Sir, It's lot easier to learn Ship Const. after going through these neatly explained basic terms. Thanks!!

Thank You soo much sir, for the easy and beautiful explanation. Preparing for Chief Mates oral exam and all your articles are really very helpful. Thanks a lot Sir. :)

Very useful. Thanks for sharing.

Very good as u explained .

Very informative ant to the point

Captain, this was a really good lesson in understanding the basics first of ship construction. I'm going aboard soon as deck cadet and this will surely help me in my pre sea course.

Thank you so much for the notes captain

v nice sir thank you

good day sir i still confuse about the " transvers " what is the purpose of the transvers member of ship structure

Thanks Sir,,!!!!!!

This is very lucid. Able to understand these very good after this article. Thank you Sir.

Sir the way you explain i love it . The best thing of your blog is that ,i love most ,after reading there is no question arise that i need explaination. thank you very much sir to share your knowledge ... keep writing

Welldone sir, well ellaborated.. Am an MSc Student of Middlesex University UK and presently we've just concluded the course 'Ship designs and Systems', your simple explanations and pictoral illustrations really helped in differentiating the structural members and their functions from each other.. Thanks once more, more grease to your elbow.

it was just awesome with picture. thanks sir

Awesome presentation of some fundamental topics in shipbuilding, very helpful thanks,

Beautiful article sir with super self-explanatory image. I would suggest this to any of my friends having trouble understanding basic ship construction terms.

Why we cant use the letter I in lettering ?

Hello Rajeev, we are considering doing a NB for a ropax ferry in India. We need a very good supdt. engineer who knows ship building well with lots of experience to oversee the project. Anyone you may know please refer to me. Thanks. Mahesh

Your explanation is awesome thanks alot

Sir thank you so much..i m preparing for class 2 and this subject i am studying from collage days but today only i understood its basics completely....your way of explainig is really so much helpful...Thank you so much again Sir

Sir share some information on trestle used in ships which carry the load during the construction and repair of the ships. Construction of trestle, the load carrying capacity and the force acting on the trestle.

Best explanation, easy to imagine

Dear Sir. Your write ups are helping me a lot in preparations for class 1 MEO. Thank you very much.

Good day Sir, The information was so much helpful for the easy understanding of the normal terms in construction. So much helpful in examination point of view also.

Reading this while preparing for an exam. So to the point and easy to understand, thank you for this resource.

Thanks, Sophie… I appreciate our insight regarding the separation anxiety in dogs. Loneliness triggers separation anxiety in the dogs which is considered as a mental disorder. paint by number kits

Is there any reason behind the name "garboard" for garboard strake...??

Used to be in the Navy, and lots I wanted to know, but didnt know. Thanks!

Great Article. Thanks for posting.

Very easy to understand and explained in a very simple,practical manner.Thanks for posting.

sir your posts are very very easy to understand i have read these terms before but never so easy to keep in mind, thanks a lot for your efforts

Very informative...

Thank you very much it really helps alot..

Can you let me know about webframe

Thank you Capt Saab for a fantastic explanation in such a simple language . It was indeed informative and enjoyable to read .

That's really nice post. I appreciate your skills, Thanks for sharing.

This is really great stuff. Hats off to you for explaining the concepts in such a simple and clear manner. Hoping to see more such content soon.

What is the difference between Transverse and Arthwartship?

Thanks sir, this presentation was marvellous . what i failed to learn during my online class over the year . i learnt it in just 10 minutes. very well explained . thanks .

May God bless you for this relevant material. Indeed,you have solved my problem in ship construction

I was trying to sign up, but i can't.

That's really nice post. I appreciate your skills. Thanks for sharing.

Thank you sir this has been very helpful

Dear Captain Rajeev Jassal. Albert Einstein said: If you can't explain it simply, you don't understand it well enough. Thank you for sharing your knowledge. Your article is very easy to understand. Great Job. Senior Marine Engineer Agustin Abaroa from México.

If you are looking for one of the best construction company in Pakistan, GVT - Geovision Technologies Pvt Ltd is the one you are searching for. https://gvt.com.pk/

Really very very helpful sir. I needed this to understand for my EDH oral exam. Love from Pakistan

Honestly I haven't find an article so simple and useful like this b4. Thanks so much sir for ur effort and knowledge shared. I have studied boat and ship Building Technology for 2 years, I'm looking forward to specializing in that. I will appreciate any of your help rendered sir. Thank you

Hello Captain, Good time,,, May you please explain regarding Middle line strake in Inner Bottom Plating with some picture? Thank you.

Thank u sir for giving good knowledge on ship

Very helpful. Thank You very much!. I now know what a stringer is! Question: What is maximum length of Center Girder in modern large ships?

Very useful posting as usual very helpful knowledge come from you always. thank.

Whether your home already has a patio area or decking in place, or it sits on a lot full of grass, we can solve all your needs fast. From new construction jobs to replace old, worn out items, we leave your decks appearing their loveliest for less each time. When you need impressive decks built fast and affordable pricing, we remain the best choice for more homeowners. http://qualityestatemanagement.com/deck-contractors/

Thanks for your support

Great explanation wonderfull

Its settle is in Port Louis, the island's capital. Sir Seewoosagur Ramgoolam (SSR) International Airport serves as its primary base. https://bmwmapsupdates.com/

Its settle is in Port Louis, the island's capital. Sir Seewoosagur Ramgoolam (SSR) International Airport serves as its primary base. https://reliablelimo.net/

Leave Comment

More things to do on myseatime

MySeaTime Blogs

Learn the difficult concepts of sailing described in a easy and story-telling way. These detailed and well researched articles provides value reading for all ranks.

Seafarers Question Answers

Ask or answer a question on this forum. Knowledge dies if it remains in our head. Share your knowledge by writing answers to the question

MySeaTime Podcast

This podcast on the maritime matters will provide value to the listeners. Short, crisp and full of value. Stay tuned for this section.

Sir i have recently completed my JET for 6 months. Now preparing for class4. This information you gave is not new to me. But the way you explained things was awesome. I am definitely not going to forget this. Looking forward for same great stuff.

Glad you liked it Akash..