I am sure all seafarers will be on same page when I say seafarers are over occupied with their own work on ship. But if deck officers specially senior officers do not understand the basic marine engineering principles, it can create a communication gap.

This communication gap can be critical during emergencies related to engine room.

But it can be of great help during engine room related urgencies if deck officers have the basic knowledge of engineering principles.

We all would agree that shipping is more commercial these days. In case of engine break down, every one ashore need to have an update every single second.

It is of great help if someone other than chief engineer (who will be extremely busy) can communicate with the shore staff.

But to do so deck officers need to understand at least the basic engineering principles.

So in this post we will discuss at least 5 of such engineering principles. As this post is mainly for the deck officers, I will not go deep into the engineering part. I will just stick to the overview of these principles.

Let us start.

1. How an engine works

I think this is basic stuff but each deck officer must know the principle of how an engine works. We all have studied this in school physics.

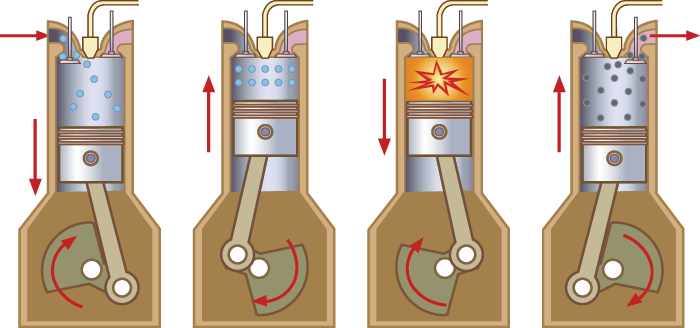

In a four stroke diesel engine, engine moves in four stages.

- In the first stage (Suction stroke) the piston moves down and it sucks air into the ignition chamber.

- In the second stage (Compression stroke), the piston moves up and compresses the air which increases the air temperature and pressure inside the combustion chamber. At the end of the compression stroke, fuel is injected in the combustion chamber.

- In the third stage (power stroke), the fuel gets ignited that produces the power which pushes the piston down.

- In the fourth stage (Exhaust stroke), the piston is pushed up because of inertia and it throws out the exhaust gases.

Watch this video on how a diesel engine works.

2. Main engine air starting system

Most of the ships would have the main engine air bottle pressure showing on the wheel house. This is an important information that the bridge officers should have on the bridge.

So what exactly is the main engine air starting system and why do we need it ?

We have discussed that there are different stages of running of an engine. For example the engine rotates the propeller because the piston is continuously moving up and down which compresses the fuel mixture to ignite it.

This is the continuous process until we stop the engine by cutting off the fuel supply.

But from where the engine gets its initial energy, when the engine is stopped and we give it a moment to dead slow ahead.

To initially burn the fuel, the piston need to move up and compress the fuel mixture. But the piston cannot move on its own. This is where starting air system is used.

This starting air is provided from the air bottle that is continuously filled by the main air compressors.

To start the engine, a minimum pressure of air is required. If the bottle pressure drops below this minimum level, the engine cannot start and we have to wait until the bottle is filled.

There can be few reasons of air bottle getting empty.

1) We have given too many consecutive starting kicks on the engine.

The starting air system of a ship is designed to provide sufficient air to give a number of consecutive kicks. For example it may be that starting air system is designed to give 12 consecutive kicks in one minute.

If during maneouvring, we have given more than 12 consecutive kicks in a minute then we may find ourself in a situation where there is no air to start the engine.

All deck officer must know the number of consecutive kick they have at their disposal. In fact this information is also a part of pilot card and master pilot exchange. Most of the times, we can get this information from the wheel house poster.

2) problem with air compressor

We usually have two air compressors for main engine. One of these compressor has the source from the emergency supply and is the emergency compressor.

Now if one of the compressor is not working, then it may be the case where one compressor is not able to fill the air bottle quick enough.

This is a dangerous situation. Even if the vessel has to sail out or berth in this condition, a thorough risk assessment must be conducted. It is important that we have the approval from the required authorities to sail in these conditions.

Even when we have all the permissions, we must ensure few points.

One of the main point is that if we have to sail with one working compressor, it is the emergency compressor that should be working.

This is because of the obvious reasons. In case of black out, we still should have a running compressor.

Even if the problem is with the other compressor, we can switch the faulty parts and make the emergency compressor workable.

3) Leaking air lines

We all have seen chief engineers so worried about the air line leak on deck as well as in the engine room. Given the severity of the situation if a compressor becomes faulty, we must understand his concern.

So leakage of air can also cause the air bottle getting empty too quickly.

Whatever the reason, during maneouvering deck officer must keep an eye on the air bottle pressure. If they see the bottle pressure dropping too fast, the engine room must be informed.

3. Turbo-Charging

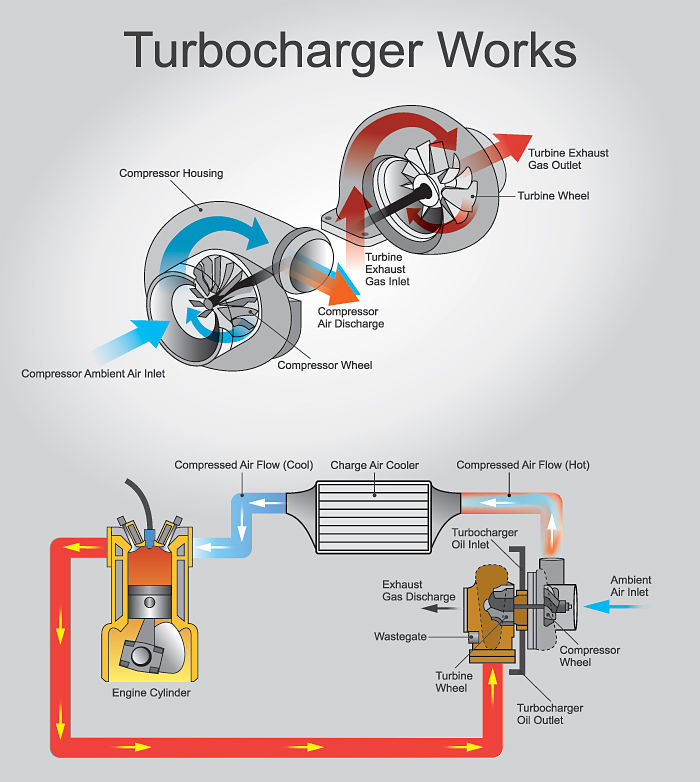

In absolute lay man’s words, a marine engine burns fuel to generate heat energy. This heat energy is used to rotate the propeller through a shaft.

The shaft and thus propeller would turn faster when more and more fuel is burnt.

Fuel can only burn when it has sufficient amount of air. For example if we inject more fuel and there is only a small amount of air available, there will be unburnt fuel in the system. There are lot of other problems in case of unburnt fuel but let us not dwell the topic beyond our limits !!!

So the point is more air we have, the better a fuel will burn and better will be the efficiency of the engine.

In simple engine (without turbocharger), it can only burn fuel in proportion to the air that it can naturally suck during the combustion process (during suction stroke). So if we want to increase the power of the engine, we need to increase the size of the engine. This way it will be able to suck more air and thus burn more fuel.

But with turbocharger, engine can get far more air and thus its efficiency increases many fold.

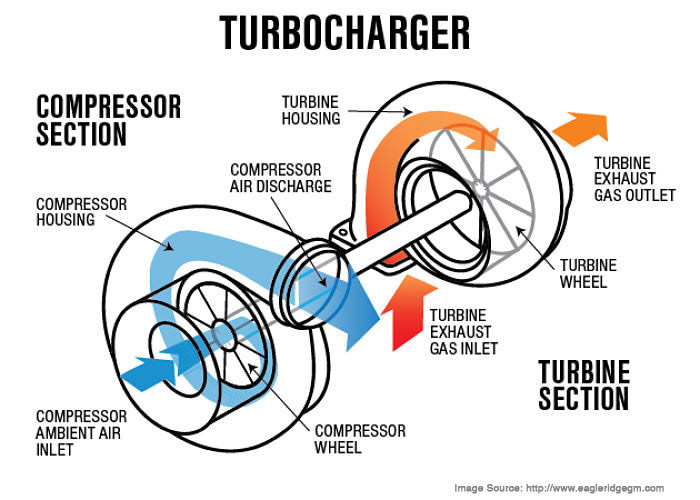

Turbocharger uses the engine’s exhaust gas to rotate the compressor which supplies the air to the engine.

It has a turbine section and a compressor section. The engine exhaust rotates the turbine wheel. The turbine wheel is connected with the compressor wheel. As the compressor wheel rotates, it draws the ambient air which is supplied to the main engine.

Cool air is more dense than hot air and dense air can carry more volume of air than hot air. So if we can cool the air before supplying it to the engine, we are pumping in more air.

So the air from the turbocharger compressor is cooled by the air cooler before supplying to the engine.

So if I have to sum up function of turbocharger in few words, it will be like this.

Turbocharger uses the engine’s exhaust gas to drive the compressor which supplies the air to the engine.

If you still in doubt as to what turbocharger of a marine engine does, watch this video.

4. Scavenging

We all have heard about scavenge space. Most of the companies would also have a specific emergency checklist for the scavenge space fire.

If we have a specific emergency checklist for scavenge space fire, we as deck officers must know about scavenge space and the process of scavenging.

We can only handle these emergencies better if we know what we are dealing with.

So what is scavenging ?

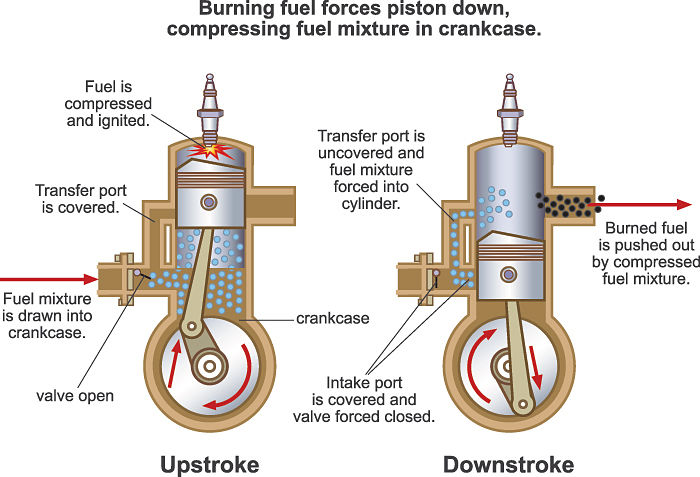

A combustion cycle of four stroke engine has following four stages

- Intake

- Compression

- Power

- exhaust

After exhaust, a new cycle will start. For an effective new cycle, the exhaust gases need to escape from the engine and fresh air need to enter.

The process of pushing the exhaust gases and drawing in of fresh air for next cycle is called scavenging.

Scavenge space is the trunking from where the engine gets the fresh air during intake cycle.

The scavenge space need to be regularly inspected and cleaned. This space can have oil because of any oil leakages inside the engine (like cylinder oil).

Air and heat inside the engine completes the fire triangle and this space can catch fire.

In case of scavenge space fire, engineers have two objectives. To extinguish the fire and to avoid the damage to the engine.

To avoid the damage to the engine, the rpm would need to be reduced.

In case of UMS ships, this reduction in rpm could be automatic.

From the navigator’s point of view we must understand that in case of scavenge space fire, the rpm of the engine would need to be reduced.

So if we get a call from engine room to let us know about possibility of scavenge fire, we should be ready for the reduction of speed. It may even require to stop the engine completely.

5. Crankcase explosion

Crankcase is the space which has many of the engine’s moving parts. But the main part that it has is the crankshaft. Quite obviously the name “crankcase” is derived from the “crankshaft”.

I am not sure if we can say that it is the case (cover) for the crankshaft ?

When the engine is running, lubricating oil used in crankshaft bearing splash around the crankcase.

This splashing creates a mist inside the crankcase but this mist is not of the level that can get ignited.

The oil mist detector fitted in the crankcase warns the ship’s engineers when the mist density has increased to the alarm point.

The mist density can increase because of many reasons such as hot spots inside the crankcase. There can be many reasons for the hot spots in the crankcase but the most common is the friction between the two metal surfaces.

The friction off course can be because of lack of lubrication or contaminated lubricating oil.

The bottom point is that whenever the oil mist gets ignited there can be explosion inside the crankcase.

Crankcase explosion is serious, far more serious than scavenge space fire.

As deck officer we must understand the severity of the situation in case of crankcase explosion and act to minimise its impact from our side too. Here is how ?

We must be aware that in case of crankcase explosion, engine rpm would need to be reduced and engine stopped. We must keep ourself ready for that and try to be proactive in quickly appraising ourself for the nearby traffic.

Even if there is no crankcase explosion, the engine rpm would still need to be reduced if the oil mist high density alarm is activated.

Reducing the engine rpm will reduce the temperatures inside the crankcase and thus will reduce the oil mist density.

Conclusion

Deck officers are not required to have a thorough knowledge of marine engineering. But knowledge of basic engineering terms used during ship operations goes a long way.

This post has discussed the five of these principles but we must try to keep gaining the knowledge of basic marine engineering term that we encounter during our tenure.

Share this:

About Capt Rajeev Jassal

Capt. Rajeev Jassal has sailed for over 24 years mainly on crude oil, product and chemical tankers. He holds MBA in shipping & Logistics degree from London. He has done extensive research on quantitatively measuring Safety culture onboard and safety climate ashore which he believes is the most important element for safer shipping.

Search Blog

16 Comments

Excellent article captain saab . It would be great if you could say something about the engine blow through that the engineers do prior departure and what actually happens in that with respect to indicator cocks and all?

Thanks Nitin.. I will try to cover engine blow through sometimes..

I think engine blow through is done to make sure there is no water leakage from cylinder jacket, No lube oil leakage into liner from a piston and there is no obstruction to any particular unit.

Rajeev nicely written. Keep posting and all the best. Rahul.

Thanks Rahul..

Engine blow through is done to make sure there is no water leakage from cylinder jacket. No LO is leaking in to liner from a piston. There is no obstruction for any particular unit.

Thanks for contributing to it Rahul..

Dear sir , recently I have started reading your blog , I have sailed with you in chembulk Savannah as a cadet. I have a few doubt regarding reasons for economizer fire , purifier room fire and what we deck officers do in such situations. Thank you in advance

Glad to hear from you Ankith.. Hope you are doing good. Economiser is usually because of soot deposits on the economiser coil. Economiser is cleaned by the engine room staff but in case it is not cleaned regularly, soot may deposit on the coil which can catch fire. The first action will be to slow down the engine and depending upon the fire size, it may require to stop the engine. Purifier room deals with purifying the fuel. There may be fuel leakages in the room which can catch fire. Purifier room usually do not require stopping the engine. The first action is to stop the supply of fuel by activating the quick closing valves. If there are specific emergency checklists for these fires, we must follow these checklists for further actions.

Sir can you please suggest some book or link which i should read to know more basics about engine terms

Can u explain for pitch test b4 arrival

This is really cool information! Thank you very much. But is it possible to add information about separators?

Thank you for providing such great information. Please find the details below for uk certificate of competency ii/i

Great post!! Thanks for posting like this unique and useful information with us. This is really awesome. Thanks for sharing this with us.

Leave Comment

More things to do on myseatime

MySeaTime Blogs

Learn the difficult concepts of sailing described in a easy and story-telling way. These detailed and well researched articles provides value reading for all ranks.

Seafarers Question Answers

Ask or answer a question on this forum. Knowledge dies if it remains in our head. Share your knowledge by writing answers to the question

MySeaTime Podcast

This podcast on the maritime matters will provide value to the listeners. Short, crisp and full of value. Stay tuned for this section.

Dear sir, initially I started reading your Q and A session which are very interesting and with that I started reading your blogs and I really liked. Everday I login to my sea time.com to find new blogs and that how's I landed up reading 5 Basic Principle of Engineering for Deck Officers. I heard the engineering terms used by marine engineers and could not understand what they speaking about, after reading the blog I can proudly say I can join them to support them as deck officer. Hats off to you sir.

Glad it could be of some help to you Kadali..