If you have the experience of dry-docking of a ship, you would agree that dry docking is a great experience.

I personally love to be on a ship due for dry dock. After all, you get to see things that you don’t see during the routine operation of the ship.

I was lucky enough to get a chance to be in dry dock in each rank I have served on. I was even lucky to experience the double-hull conversion of a tanker during dry dock.

But if you have not been to a dry dock, there would be one thing that might come to your mind on hearing the word Dry Dock. And that is dry dock calculation that we read in ship stability, probably during our Mate’s exams.

That’s purely the theory part. And I believe theory without practical experience is just a theory.

So here I am going to write about the practical aspect of taking a ship to dry dock.

But before I proceed, in layman’s terms I will summarize what we had read about dry docking in ship stability.

We read and understood these things

- The time from “when Stern touches the blocks” to when “full ship is on the blocks” is the critical period.

- During the critical period, the vessel’s GM reduces. This is because the vessel’s ‘Gravitational center G moves upwards when Stern touches the blocks.

- It is required and a good practice to have the least trim while docking so that the critical time is minimal.

Preparing for Dry Dock

Well, I am not going to the company-specific parts of dry docking, like preparing repair specifications.

I will specifically be talking about taking the ship into the dock and making it sit on the blocks.

And then, of course, bringing the ship out of the dry dock.

Days before the planned dry dock, Dockmaster will make the first contact with the ship. He can do so either directly or through the company representative such as superintendent.

The dockmaster has a huge responsibility for calculating the stresses on the dock as well as the ship’s structure. Any miscalculation can lead to serious accidents resulting in huge damages. These damages can be to the ship as well as dock itself.

The dockmaster is trained for block arrangement and stability during dry-docking. For all these calculations, the dockmaster needs certain information from the ship. Among other things, he will ask for

- a copy of Vessel’s Docking plan

- Arrival Stability condition-docking condition

- Pre-docking condition

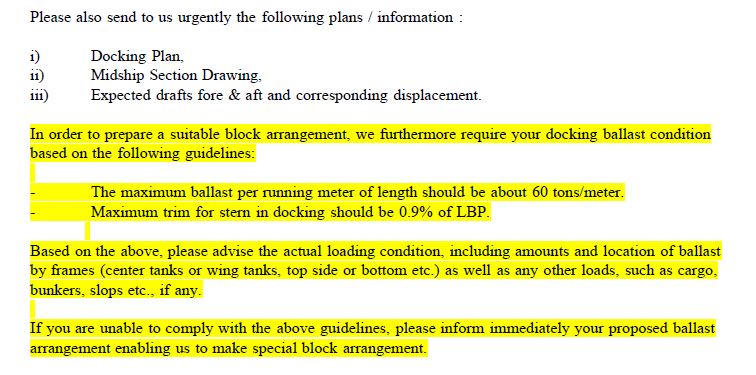

Some of the content of his email might look something like this

From the docking plan, dock master wants to know

1) Hull structure so that he can arrange the blocks to support the ship’s hull.

2) locations of transducers for log and echo sounders so that these do not come beneath the blocks.

3) Location of sea chests and drain plugs for the same reason.

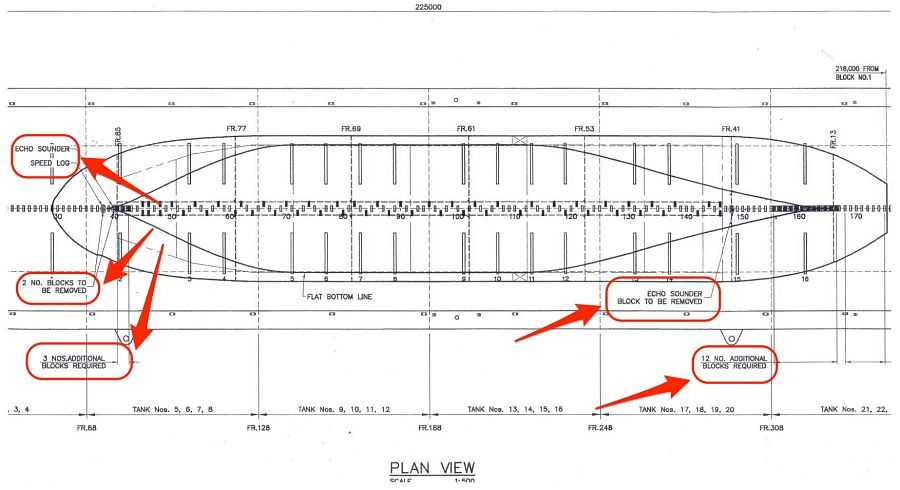

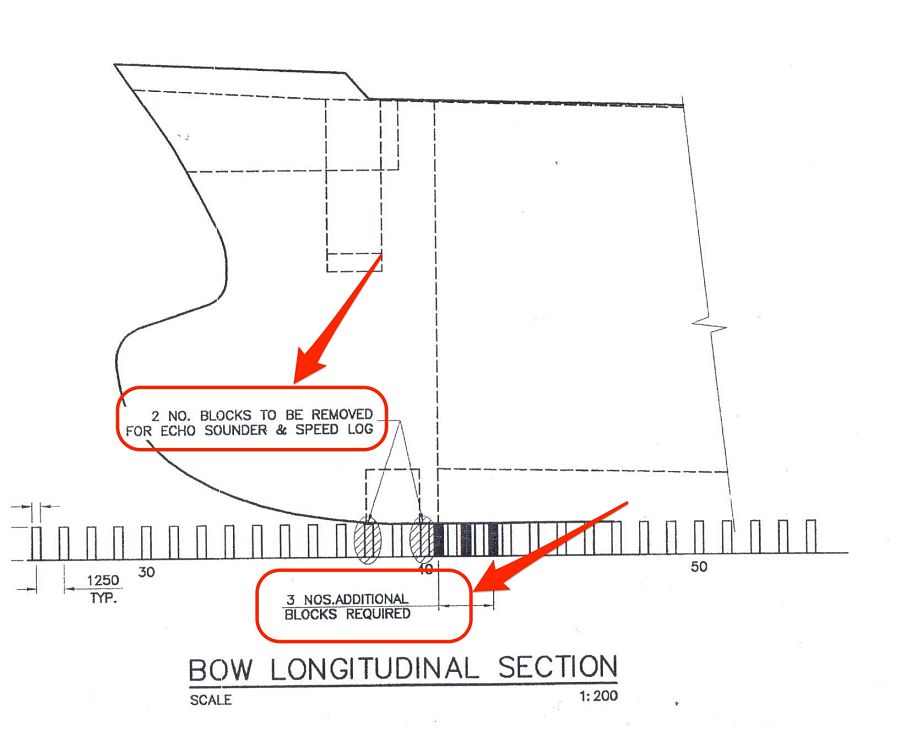

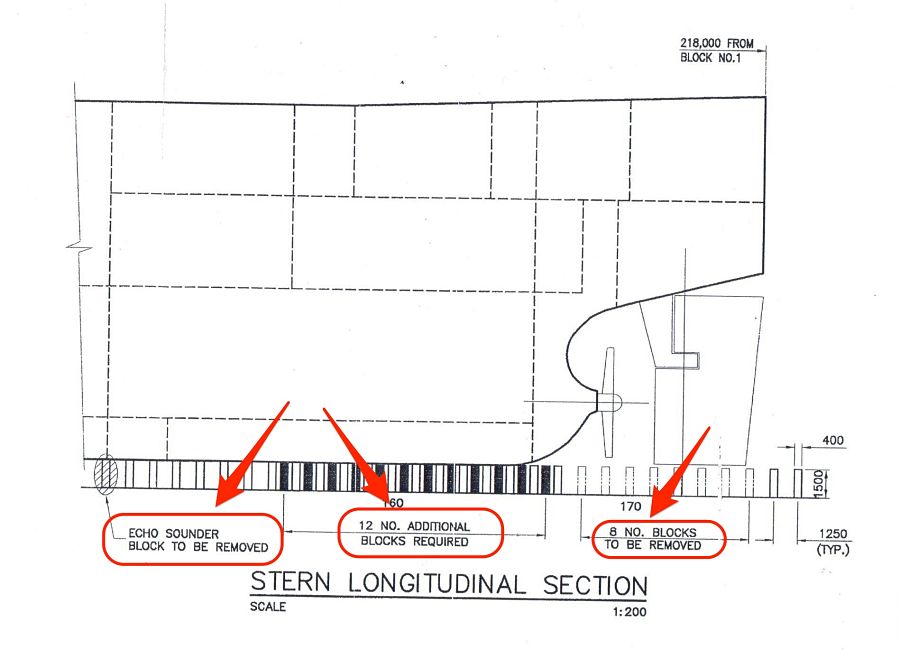

Based on the docking plan provided by the ship, the dock master prepares his own docking plan for the ship. Below are some of the sections of the actual docking plan prepared by dockmaster for s ship arriving for dry dock.

As you can see, the dock master has planned which blocks he needs to remove and where he needs to put blocks. He also has specifically marked the location of echo sounder and speed log.

Have a look at the closer view below, which is again from the same docking plan prepared by dock master.

I think the above image makes it more clear about what dockmaster is trying to achieve from the docking plan. If you want to see the stern view too. Here is it.

And this is no theory. This is an actual docking plan prepared by the dockmaster for a ship arriving at dry dock.

I know I am kind of repeating myself but I can’t say it enough. That is because I get excited to see real things than just theory.

Stability condition and weight distribution

Apart from the docking plan, the dock master would ask the arrival weight distribution of the ship.

There can be up to 4 stages for which stability calculations are required. These stages are

- Arrival Drydocking port

- Pre-docking condition

- Ship sitting on the blocks but dock not yet empty (also called wet condition by dockmaster)

- Ship on the blocks and dock empty (called Dry condition by docking master

Let’s discuss each of this condition

Arrival Drydocking port

On arrival dry docking port, you need to have the least possible ballast. By least possible I mean, the propeller should be immersed. And also you should be complying with all stability requirements.

Pre-docking stability condition

So we know that we cannot arrive with zero ballast as our propeller needs to be immersed and the ship needs to be stable.

But what is the logic behind having the other three conditions? Why can’t we just remove all the ballast and go inside the dock?

Let’s understand the logic behind these conditions

Docking with zero ballast is the ideal condition. But most of the time this would not be possible. That is because a docking master would limit you for the maximum trim that you can have. In zero ballast condition, your trim may be more than 2 meters.

Dockmaster would want you to reduce the trim to around 0.5 meters. This depends on the dock on how much trim you can have before docking.

We have already discussed the reason for the need for the least trim while docking. This is to have the least critical period. More trim we have more will be the time required to bring the vessel from stern on the block to full ship on the block. And this is the critical period with the least GM value. We do not want to have the ship in a critical period for a longer time.

Most of the ships will have considerable stern trim in lightweight condition. So most ships will need to have some ballast forward in Pre-docking condition.

The amount of ballast would depend on how much trim dockmaster has advised you to have.

Stability condition while the ship on blocks but dock not empty

When the ship is on the blocks, you have already passed the critical period. Dockmaster will tell you to start deballasting. The only concern dock master will have is the ship should not refloat.

The ship can refloat if dock deballasting cannot compensate for the decrease in the draft because of deballasting.

The condition is monitored by the dockmaster and he would tell you how much ballast you can remove in this condition.

But the question is why the dockmaster need the vessel to remove the ballast concurrently when he empties the dock?

This is because dock water does not want to have more weight on the blocks. When the ship is sitting on the blocks but has water inside the dock, there is a certain amount of buoyancy ship has. This buoyancy acts like upthrust which reduces the effective weight acting on the blocks.

This condition will be discussed by the dockmaster and he will advise when and how much ballast you can remove.

As I said earlier, the dock master bases his calculations on not to allow the ship to refloat.

Ship on the blocks and dock empty

When the ship is on the blocks and there is no danger of ship re-floating, dock master will tell to take out all ballast.

Dock masters sometimes call this condition as the Dry condition.

Procedures for taking the ship to dry dock

Now that we know about the stability part, let’s look into each stage of taking the ship to the dry dock.

Arrival to the dry-docking port

As I mentioned, you would arrive with the least ballast. That would be arrival dry docking port condition. Even though the ship will be complying with draft and stability requirements, but the ship will be light. Lighter than usual ballast condition. So before you arrive at this condition, it is important to scan the weather reports. You would not want to arrive in a light condition if the weather prediction is rough.

Most of the time, the ship is taken to the lay-up berth before going into the dry dock. If not, the vessel needs to be at anchor for deballasting to arrive at the Pre-docking condition.

While at anchor, dock safety inspector will board the vessel. He will do the gas check of all the compartments to make sure that the vessel is gas-free. He will then issue a gas-free certificate. He will also give safety booklets of the dock which will have all the safety regulations of the dock.

Docking of the vessel

The vessel will dock when it has achieved the pre-docking condition. In this condition, the vessel will have the least ballast to achieve the required trim.

Before docking, the dock master will board the vessel. He will discuss the docking procedures with the master and chief officer. He will give the mooring arrangement plan while docking. He will specify Panama leads from where the moorings will be passed.

Apart from this, he will also discuss the ballast condition at each stage.

For shifting to the dock, the pilot will board the vessel. As the ship’s engine will not be available, the ship will have a number of tugs to move the ship to dry dock. The number of tugs would depend on how big the ship is and how powerful the tugs are. In any case, all ships can expect 5 tugs or more.

Out of these 5 tugs usually, 2 will only be assisting for pushing. Different docks can have different arrangements for making fast the tugs. It will all depend upon the location, tidal current, and local factors.

One of such arrangement can be two tugs made fast forward, one made fast aft and two tugs standby. The one tug made fast aft will have one line on each side of the poop deck to have better control in handling the ship.

Depending upon the dock, the ship will either enter stern in or bow in.

The pilot will bring the ship to parallel to the dock. When the stern (or bow whichever is entering first) is close to the dock knuckle, the docking master will take over from the pilot. Docking Master is different from dock master. Docking Master may not board the vessel and will be giving instructions to the tugs from the dock itself.

When the ship is inside the dock, the ship’s crew needs to pass the mooring lines as per the agreed mooring arrangement. Usually forward and aft will have two lines on each side. Out of two lines on each side, one on each side can be a shoreline. But this can be different and mooring arrangements will be advised by the dockmaster.

When the ship is made fast with the moorings, docking master will sign off and dock master will take over.

The vessel on the blocks

Before the dockmaster starts to remove dock water, a diver will make an underwater inspection. The diver will ensure that echo sounder and log sensors are clear and not sitting under the blocks. He will also ensure physically that the vessel’s centerline is in line with the blocks. It is a good practice to switch off the echo sounder and speed log now.

After the diver has made his inspection, the dockmaster will start pumping out dock water.

Dockmaster will let the vessel know when Stern has touched the blocks and when the ship is on the blocks.

After the ship is on the blocks, the dockmaster will tell to start pumping out the ballast to arrive at the wet condition.

As the dock water is being pumped out, at one point the water will go down from the generator cooling water sea chest.

After this point ship will get power supply from shore.

A shore electrician will board the ship (Through basket and shore crane) and make arrangements to connect the shore power. Ship’s Electrician should coordinate with him to have the shore power connected.

You should check if shore power will be enough for running the ballast pump and mooring winches. If not, this should be discussed with the dockmaster in advance. He will then ensure that the water level does not go below sea chest until you have pumped out the required ballast.

Once on shore power, dock master would continue to dry the dock. He will tell you to take out all the ballast accordingly. You may do so with gravity as the same might be more effective.

Once the dock is dry and ship sitting on the blocks, you can line up to deballast all ballast tanks by gravity. This is to let all the water drain whatever is left in the ballast tanks.

So now you have already brought the ship to the dry dock. It is a wonderful view to see the ship out of the water. You should not wait to go down in the dock and have a look at her.

Removing the Drain plugs

The Ship repair manager will now request the chief officer to witness the removal of the bottom plugs.

As you know, each tank which forms part of the hull has a bottom plug to drain the water in dry dock.

Removing bottom plugs ensure that the tanks are empty and dry. As the bottom plug of each tank is removed, it is important to label it. This will ensure that bottom plugs are not interchanged while fitting back.

Though plugs of all the ballast tanks are of the same size, it is best practice to fit back plugs which belong to each tank.

If you wish to experience how we remove the bottom plugs, watch this video.

Departure from Dry Dock

After a few hectic days in dry dock, it would be time to leave dry dock. We need to be equally attentive in leaving the dry dock as we were while coming into the dry dock.

Before dock master floods the dry dock, all the underwater things need to be in order. This includes sea chests, ICCP system, echo sounder sensors, log sensors, and drain plugs.

Echo sounder, log and drain plugs are tested for air and water tightness. Testing involves first putting soap solution around the drain plug. Then we create the vacuum around the drain plug and look for any bubbles.

If you have never experienced this testing before, here is a video of the testing the drain plug.

After all these integrity tests are complete, it is time to leave the dry dock.

The best approach of leaving the dry dock is to follow exactly how the ship came into the dry dock.

It would involve

- Filling the ballast to bring the ship to wet condition.

- passing the lines as was in the arrival condition

- Flooding the dock

- Filling the ballast to pre-dry dock condition

- Flooding the dock up to the level where the ship is fully afloat.

- Disconnecting the shore supply and taking ship’s generators on load

- Taking the ship out of the dock with the help of tugs.

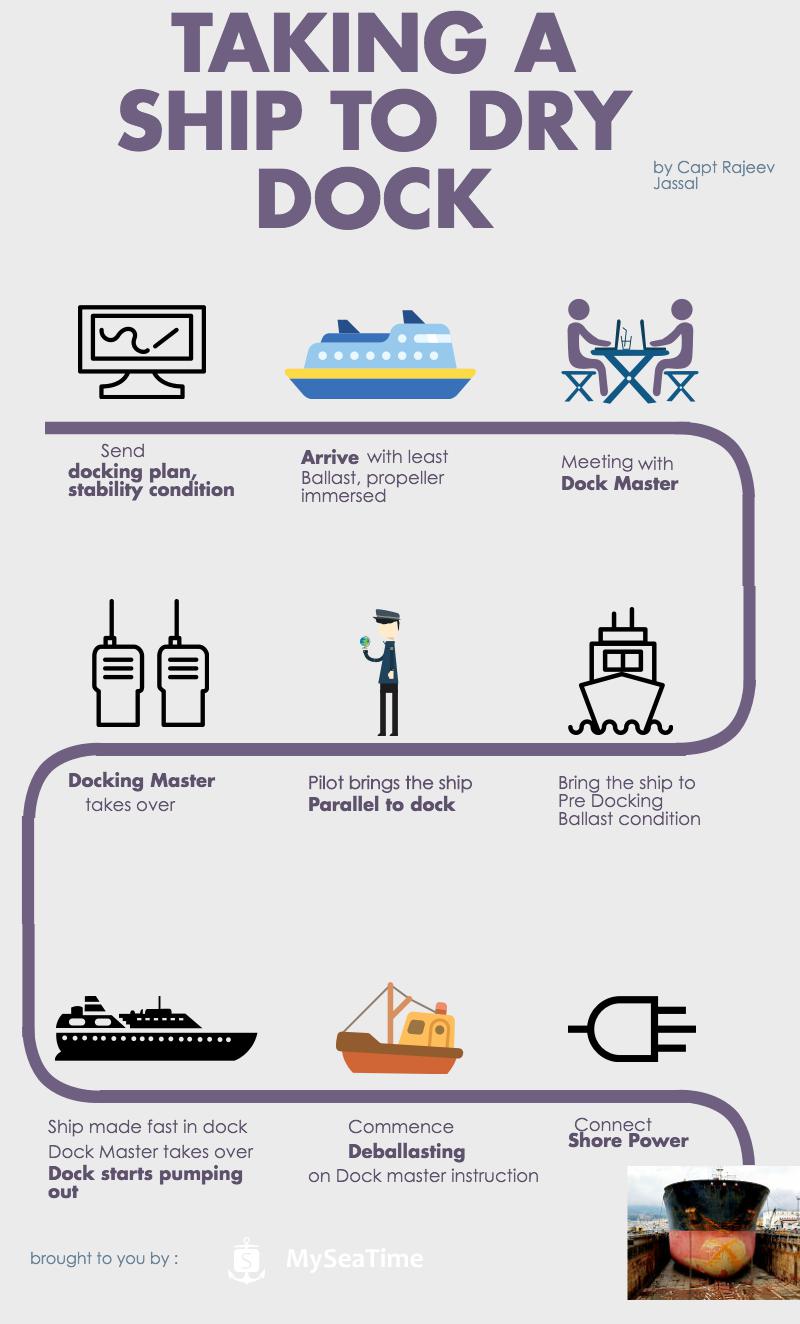

Finally to summarize the process of bringing a ship to the dry dock, here is an Infographic

Conclusion

Drydocking is a great experience for those who do not want to stop learning. The special thing about dry docking is that there are plenty of things that a seafarer can learn each time he attends a dry dock.

While it might seem to be a difficult process but if we view the whole process logically, it would seem a routine.

If you are going to a dry dock, Enjoy the learning process. And let me know in the comments below if there was anything that should form a part of this guide.

Share this:

About Capt Rajeev Jassal

Capt. Rajeev Jassal has sailed for over 24 years mainly on crude oil, product and chemical tankers. He holds MBA in shipping & Logistics degree from London. He has done extensive research on quantitatively measuring Safety culture onboard and safety climate ashore which he believes is the most important element for safer shipping.

Search Blog

124 Comments

Loved your web blog and its excellent.

Glad that you liked it Rag..

Very informative and useful.

Glad you found it useful Lokesh..

Although the principal of testing a bottom plug is the same, the video above is actually a vacuum test to ensure that a transducer head (most likely an Echo Sounder) is properly sealed.

You are absolutely right John.

Awesome sir, i found it very much useful during drydock of NCC ABHA. It was my first drydock.

Glad you found it useful Sanjay. I hope the dry dock of ABHA went all well...

Excellent explanation sir.

Glad you liked it Amin..

sir pl post article about legal requirement during dry dock for chief mate candidates this blog is really helpful for orals

I will include that in one of the future blogs Ankit..

Dear Rajeev Sir: I was surfing through for Keel Blocks and types of keel blocks for dry docking, and stepped over your blog. Its amazing to know the facts, and its the same even with us in dockyard. I have been lucky to see a ship docking and undocking. Can you share some of details on keel blocks, it would be a great help to me. Regards, Ramamurthy, Visakhapatnam, India

Glad you found it useful Ramamurthy. I have one post on ship structures. Hope that could be of some help.

very informative and great article for orals prep !

Glad you liked it Abhimanyu..

that is good share for one

Thanks..

very informative article sir..helped a lot

Glad you liked it Jaison,,

A very good and concise explanation especially for crew going to dock for the first time.

Thanks Mohammed..

Thank You very much sir for this wonderful article. Immensely helped me while answering my mates orals. Had never been to a drydock but could visualize perfectly.

Glad that it could be some help to you Swapnil..

Thanks a ton for the article sir.Can you tell me the name of the instrument which does vacuum test of bottom plug?

There is no special name for this. It is simply called "Leak Test Vacuum box".

Sir can u pls tell me how come dock master will know that ship bottom had touched the blocks,What are the methods?

He knows the height of the blocks and when the draft of the ship is equal to this height, he would know that ship has touched the blocks. In case of floating dock, he will notice the additional weight on the online loadicator of the dock.

Sir, The way you explained is very simple and one can parallely imagine....just got the feeling that I was physically witnessing the whole scenario.....felt good reading....Thank u

Thanks Satish. Glad you found it interesting..

Sir,this an awesome post as the others from you,very helpful for orals.Can you post something simple regarding stability,it would be quite helpful.Thanks.

Glad you liked it Soumen. I will write on stability soon..

Hi. excellent explanation. i have a question about dock master responsibility for any accident happened for the ship , dock crew and dry dock itself during docking & un-docking the vessels specially if during this procedure fatal accident causing human life to be lost. thanks a lot

It is not the dock master alone that would be responsible but the dry dock company. In case of fatal accidents, the ship owner might appoint a maritime lawyer and make monetary claims for the family of the seafarer.

Excellent blog sir, very informative, very practical , beautifully explained. I had few doubts about it, got cleared. Thanks a lot sir

Glad you liked it Neeraj..

Sir when to do the de-ballasting once the Ships is already inside

Dock master will advise when to start the deballasting. It is started when ship is aligned to the blocks. Dock master will advise to keep the minimum draft to keep the A/E running. When the shore supply is connected he will advise to keep on deballasting.

Good day sir. Maybe i'm off the point a bit but what usually happens with staff members during a dry dock period of 2 to 3 weeks? For example on a cruse ship with hundreds of employees from all over the world.

The required staff stays onboard. I do not know about cruise ships but I guess the catering staff and all other staffs required for passengers are sent on leave and staff responsible for the operations of the ship remains on board.

Excellent blog....Sir. Accidentally stumbled upon this blog and though not connected with Marine Engg. ; enjoyed reading.. Am basically a Mech. Engr.... enhanced knowledge.

Thanks, Dhiren...

I'm glad to find this blog, I loved your complete explanation, it made it all clear for me . Thank you.

Glad you liked it, Adriana...

m making presentation on dry dock u made my job a piece of cake with this data .

Glad you found it useful Shiven...

well explained and you made others realize that its not just sailing a ship into the sea.

Glad you liked it, Moses...

Thank you very much for such a detailed explanation.

Glad you liked it Arvind...

Sir, It is possible to Dry dock a ship with trim by head??

Nice article. During dry docking what is the normal procedure for the electronics. Will the AIS, radar, etc be turned off? Thanks again!

There is no such requirement but if any yard specific requirement, then yard safety officer will let the vessel know in advance..

Thank u a lot for information and we need more data about tugs maintenance and tug docking if u don't mind

Thnks for the vast imformation,So every time the new ship come,we can arrange the block according to that ship??

Perfect explanation sir i will be glad if you also explain about bilge blocks and shores and how they are placed

Excellent sir. This is the best article written in excellent and simple way. I just very happy.

Excellent article, there is a repeated question asked in Master exams, How will you drydock a vessel with forepeak in damaged condition??

Sir kindly advice why they need midship section plan and how it is useful in drydocking

Why ship is trim by astern while dry docking and why it can't trim by forward

Thanks for the step by step procedures regarding chiefmate's responsibility for preparation dry dock. It has been a great help and got the idea on how it goes. A great preparations for my orals class 2 as well. Thank you so much Sir

I appreciate you sharing a complete guide on how to bring a ship to dry dock. I've always wanted to learn how to do this because it has always been my dream to have my own boat or yacht. The tips or steps you've provided would surely help as a reference if I ever get to have my own boat in the future. Thanks. http://www.customdocksllc.com/

Stern trim to be 0.9% of LBP as required by dock master My quiery is where is this info given?. MMD SURVEYOR question

Hello, Good day Sir, My question is wrt stability prospects, where will be P when the vessel is sitting all over the blocks. This is a question frequently asked in MMD orals for Master candidates. Thank you in advance.

Good day Sir, I have question regarding Crude Oil Washing for Crude OIl Tankers entering DD. Is there any specific requirement for Amount of Water used and No of minimum cycles to be carried out before entering DD.?

Very informative and detailed explanation sir. We can find the theory part on other parts but all the topics disccused bu you are added with practical knowledge and its implementation.

Very informative and detailed explanation sir. We can find the theory part on other sites but all the topics disccused bu you are added with practical knowledge and its implementation.

Awesome sir. I can't explained you. Just one word- mind blowing. Sir i have one question to you. What is the name of Special keel block use in dry dock with loaded cargo??

Comment* Thanks for your effort, very useful informations. God blessed you Sir.

Sir , last month during my chiefmate oral surveyor asked , use of shores in drydock. I didn't know the answer, please sir can u answer this question, thanks in advance

Very well explained about Docking and Undocking of a vessel. But if possible, can you pass information regarding vacuum test of drain plugs before undocking.

PLEASE ADVICE ON BELOW QUESTION FOR WHICH IS FREQUENTLY ASKED IN ORAL FOR MATES & MASTER. MAINTENANCE ON ANCHOR & CHAIN LOCKER IN DRY DOCK?

beautifully explained,vodeo is real spice to the contents.

Thank You for a great information

very good explanation especially for crew going to dock for the first time.

capt.rajeev, thank you for such beautiful explanation. can you please explain procedures for dry docking with forepeak tank ruptured.

Excellent blog sir

Good day Sir, I have much knowledge and experience from your article. One of the condition is confusing me, that de-ballast operation during pumping out of dock water when the ship overall sits on all blocks. Why do we need to de-ballast after approved the ship's stability and condition by the dockmaster? Purpose? Is this operation optional requirement from the dockyard or essential to do? Appreciate your reply. with best regards, Win KS

What will happen to ECDIS or How does ECDIS afftected when the ship is already on the blocks at Dry Dock. This question was asked many time by MCA Surveyors in UK.Cany anyone share the answer to this ??

Did you find the answer? if you found pls share.

THE SPEED LOG SENSOR IS IN-OPERATIVE WHEN THE VESEEL IN ON THE BLOCK. REST THE ECDIS WORKS FINE!!!! YOU CAN DO THE PASSAGE PLANNING AS YOU CARRY OUT AS NORMAL IN SEA GOING CONDITION.

THE SPEED LOG AND THE ECHO SOUNDER ----- CORRECTION FOR THE ABOVE

Excellent work vauable information thank you captain

Sir kindly add the clearance check near shaft I once witnessed this but have no clue about do & don’t.Kind of blade type material used to demonstrate. I haven’t raised question to my C/Eng so kindly explain

I enjoy what you guys are usually up too. This sort of clever work and coverage! Keep up the wonderful works guys I’ve added you guys to my blogroll.

I’d love to be a part of group where I can get advice from other experienced people that share the same interest. If you have any recommendations, please let me know. Thank you.

Your article provide such a great information with good knowledge. Sir please if u could explain what all checks to be carried out after vessel is out of drydock and at sea... Thank you very much for sharing such knowledge.

This helped me understand some good ways to get started. Thank you.

Dear Rajiv, we are looking for documenting process for dry docking and PMS for Barges. Please contact me on suhag@mastermindindia.in or +918460358894 if you can help

Great article sir... as usual ....very informative ..

Good day sir I have a question regarding the critical period during undocking does the vessel experience this during undocking also as I have not found any literature on it anywhere

It was a very useful blog sir Can u please also explain why we keep trim by head when we make departure from drydock?

A great tool for cleaning ship areas which you can't reach is the telescoping wand from https://bestcargurus.com/. You might want to check it out.

Dear sir. Your article is very useful for me.i have some doubts regard drydock. Please clarify my doubts. 1) why ship enters in dock with trim by stern. 2). How to paint the area between keel blocks and keel.

The main objective in carrying out dry docking is to ensure ships are operational and to maintain their class license. Structural machinery and various components are subjected to inspection and maintenance to ensure sea worthiness. Dry docking is also required if a ship has sustained damage to the under water structure due to grounding, collision or any other damage which will affect the water integrity of the ship’s hull.

Captain you love what you are doing and this is obvious...thank you for sharing your knowledge.

Even though I had 2 DD experience, i see a new things in your article sir. Loved it very much. As an engineer, Hardly have a chance to see all these maintenance outside hull.

When ever you are at the dry Dock. You add some knowledge to your job. Great experience though.

Thank you for posting your blog, in your blog, there is a lot of useful information about Dock. Keep sharing such a nice knowledge with all of us. https://designdockcompany.com/

hie sir you pls share, how to DD a ship in emergency if a ship is loaded , what precautions to take ?

Thank you for this unknown to me yet interesting & easy explanation sir. I didn't get any chance of docking yet but these words made me feel like I was there already.

Before going for Drydock what things will be prepared in relation to LSA and FFA... Question was asked during the Orals

Thank you for providing such great information. Please find the details below for chief mate oral prep

The content of the post is really helpful. Do you have any procedure for keel block removal under load? Thanks

The content of the post is really helpful. Do you have any procedure for keel block removal under load? Thanks

Great post. I was once checking constantly this weblog and I'm impressed! Extremely useful information specially the closing part. I maintain such information much. I was once seeking this specific information for a very long time. Many thanks and best of luck.Infographic Submission

very informative and your explanation is wonderful

lovely information as we have been looking for.

Hello sir..do we need to shut down gyro as well when vessel is docking?

Thank you for this informative piece of writing. I like the way you have explained even the minor details, which will let anyone to understand the whole procedure very well. Keep sharing such good work. Regards, Economy Dock Seawall And Dredge Company

It is a good write up this as added to my experience being in dock with vessels. Please sir, explain the precautions to be take to ensure successful docking of a vessel.

Thanks Captain, I am preparing for my chief mates orals. This is the best explanation I have ever came across, Normally don't leaves comments haha, But just wanted to say a big thank you. I have been to dry dock only once on my first ship as a cadet and can now relate to much more after reading this. Anir from South Africa

Excellent explanation sir, could you please elaborate a little about dry and wet sounding of tank and why do we take them ?

I felt like I was actually in the drydock while reading the post. Great explanation Sir.

Excellent blog sir, very informative, very practical , beautifully explained. one Doubt why not vessel enter dock in Even Keel condition instead of 0.5 trim by stern.

Am looking for someone to take me to dry docking with all these tips have read to see for my self practically because I really enjoy reading it

Sir when ship is fully sitted on blocks where is the posn of G

Leave Comment

More things to do on myseatime

MySeaTime Blogs

Learn the difficult concepts of sailing described in a easy and story-telling way. These detailed and well researched articles provides value reading for all ranks.

Seafarers Question Answers

Ask or answer a question on this forum. Knowledge dies if it remains in our head. Share your knowledge by writing answers to the question

MySeaTime Podcast

This podcast on the maritime matters will provide value to the listeners. Short, crisp and full of value. Stay tuned for this section.

A wonderful explanation Sir , though I haven't got a chance to be at drydock , but I could Imagine the process .. Thanks.

Glad that you liked it Jayraj

Excellent explanation sir

Glad you liked it Anooj..

Very informative. I now have an good understanding of what can be expected when it comes to Dry Docking.

hello hello sir if you just tell me the safety precaution that take place after entering the dry dock i will be grateful