We do so many things to make sure that ship owners get the maximum out of their investments on buying and running a ship.

We make sure that there are least constants on the ship, the ballast is pumped out to the last drop and many other things like these.

All this to make sure that we have the capacity to load maximum cargo and ship owner has a chance to earn maximum from it.

But while we do all this, sometimes we just fail to do the simpler things right.

Things as simple as cargo calculations.

This is something a chief officer cannot afford to do it wrong.

But here is the thing. It is sometimes difficult to get a hang of these calculations. There are so many tables to use and so many terms that float.

Sometimes it is difficult to understand which one to use and why.

But don’t worry!!! This article would aim to simplify the cargo calculations on tankers.

Here we go.

Basics about Volume and weight

Before we proceed to the complex things, it is better to start with the basics.

Volumes and weights!!!

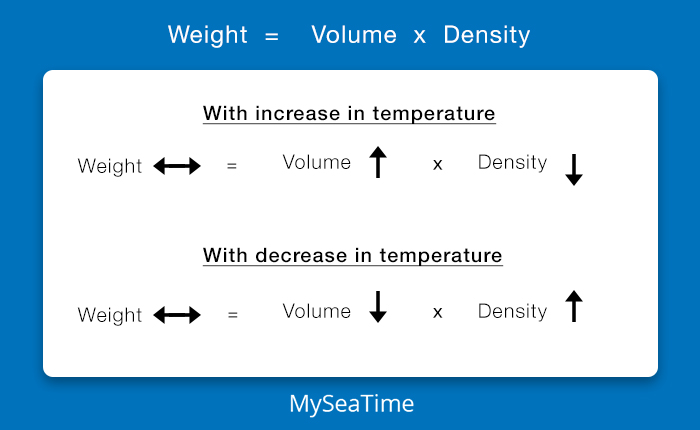

Volume changes with temperature but the weight remains the same.

Even when we hear some weight of cargo, let us say 30000 Tons of cargo, there are two things that we need to be aware of.

1. Unit of weight

What is the unit of this weight? Is it

- Metric Ton

- Long Ton

- Short Ton

2. In air or in Vacuum

Apart from the units, weight is measured in air or in Vacuum.

Even though on ships it is more common to measure the cargo weights in the air, sometimes you may find that the charterers would give the requirements for measuring weight in Vacuum.

Remember, for stability and draft calculation we still would need to use the weight in air.

Coming back to the topic, can you guess for the same amount of cargo which weight would be more? Weight in air or weight in Vacuum?

No problems, make a wild guess even if you don’t know.

Well, the weight is Vacuum is always more than the weight in Air.

This is because, like with water, air (and any other medium in which the weight is present) would offer some kind of buoyancy which reduces the weight.

In the vacuum, there is no buoyancy and hence the weight is more than the same weight when measured in air.

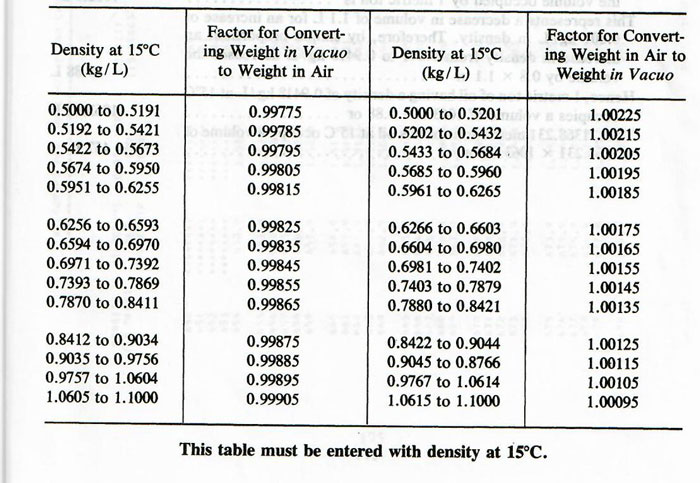

Converting weight in Vacuum to Weight in Air and vice-versa

Ok, so now here is the first thing that we can learn. How to convert weight in Vacuum to weight in Air?

The first page of the ASTM table 56 provides the factor for converting weight in vacuum to weight in air and vice versa.

Basics of cargo calculations

Ok, now let us get back to basics of cargo calculations on tankers. And it is not that complicated.

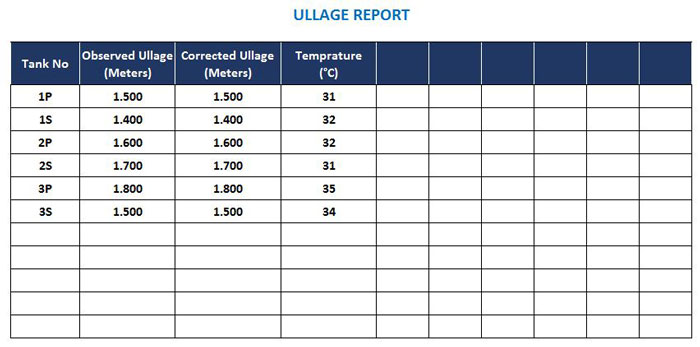

We first measure ullage (or Sounding) of the tanks by UTI tape (or radar gauge in CCR).

We also measure the temperature of the cargo preferably at three levels and take the mean of these three temperatures to get the temperature of the cargo.

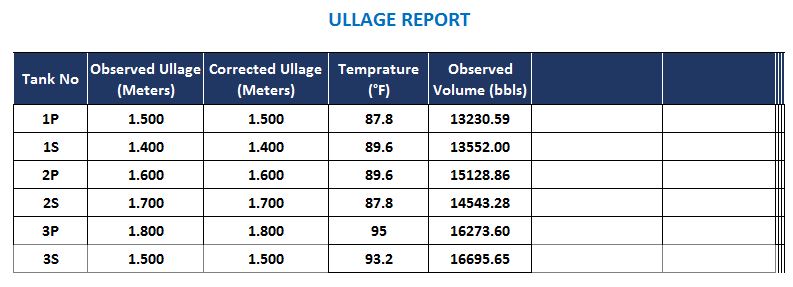

So here is what we have.

Now we get the volumes for each of these tanks for the corrected ullage that we have got.

This will be the volume at the observed temperature. Remember volume changes with temperature.

This will be the volume at the observed temperature. Remember volume changes with temperature.

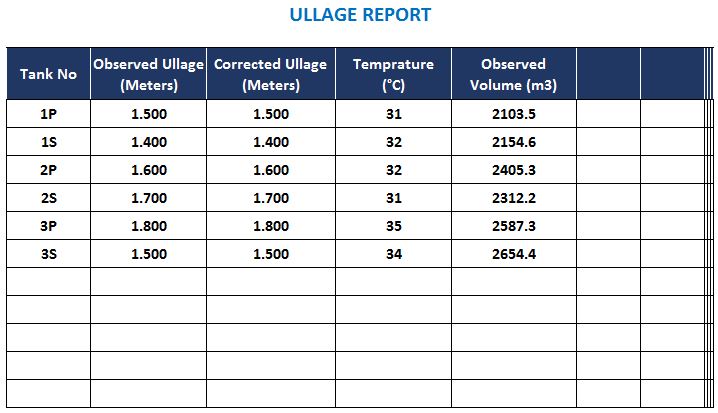

Let us say we got the volumes from the ullage tables and the volumes for each tank are as per below.

As the volume changes with the temperature, this cannot be the measure of how much cargo we have loaded or discharged.

We need to convert the volumes to the weight of the cargo in each tank. We need the density of the cargo to convert the volume of cargo to the weight.

And as the density also changes with the temperature, we would need the density of the cargo at the cargo temperature to convert the observed volume to weight.

If that was not enough, humans on this planet earth have managed to confuse it further.

- Volumes are measured in cubic meters at some places and barrels (like in the US) in other

- Weight is measured in Metric tons at some places and in long tons at other places and barrels at 60 deg F at other places.

- Densities are measured as Density in t/m3 at some places and API or specific gravity at other places

But don’t let all these confuse you. I won’t let you confuse yourself. Take a deep breath and read on.

First, check what cargo surveyor has provided you.

The cargo surveyor will provide

- Density at a particular temperature and correction factor

- A Table of densities at different temperatures

- Density at 15 Deg C and ASTM table to use

- API Gravity at 60 Deg F and ASTM Table to use

Let us calculate the weight of cargo in each of these situations.

1. Density at a particular temperature and correction factor

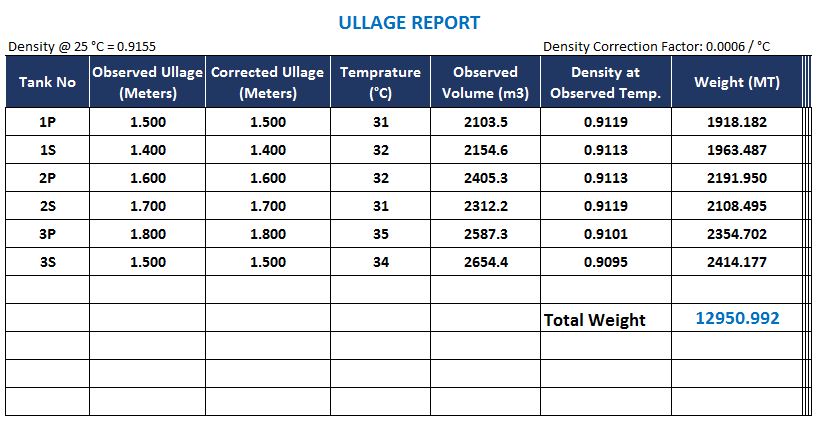

So let us say that cargo surveyor has provided us with the density at a particular temperature and correction factor.

Let us say the provided values are

- Density at 25 Deg C: 0.9155

- Density correction factor: 0.0006 per Deg C

This means that at every degree rise in temperature, the density would decrease by 0.0006.

This means that

- Density at 31 Deg C would be: 0.9119

- Density at 32 Deg C would be: 0.9113

- Density at 34 Deg C would be: 0.9101

- Density at 35 Deg C would be: 0.9095

So, in this case, we just apply these densities to get the weight of cargo in each tank and thus the total weight of the cargo.

Here is how the ullage report will look like.

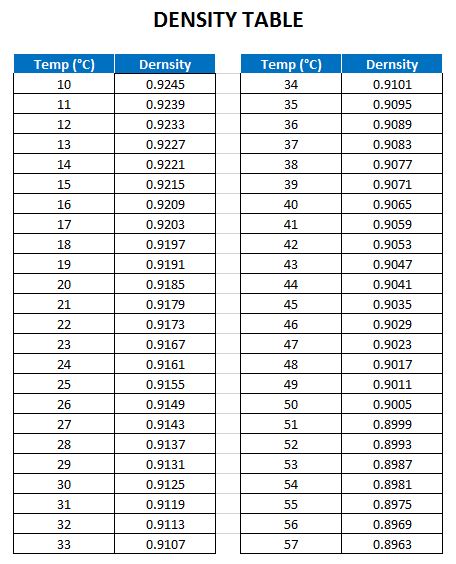

2. A Table of densities at different temperatures

The cargo surveyor may provide a table of densities at different temperatures. This is even easier than the previous section that we discussed.

The density table could look something like this.

The cargo calculations, in this case, are also easy. We just take the density of the cargo to the corresponding cargo temperature that we measured.

Rest of the calculations is the same as what we discussed in the previous section.

If the cargo temperature is between two values in the density table, we just interpolate to the get the density at the desired temperature.

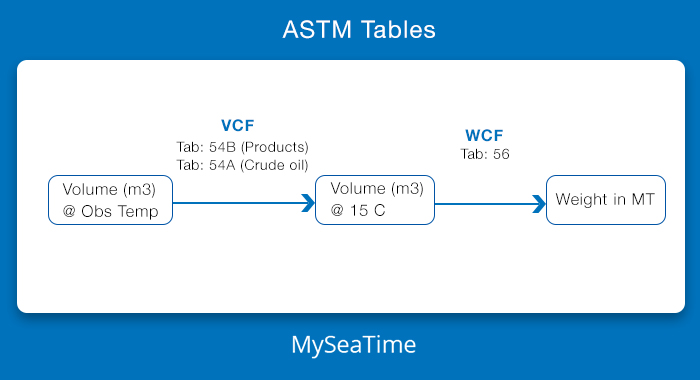

3. Density at 15 Deg C and ASTM table to use

The previous two methods are useful and applicable for cargoes the density for which changes proportionally with temperature.

These methods are mostly used for calculation of chemical cargoes.

But for petroleum products and crude oils, ASTM tables are used for calculating cargo weights.

ASTM tables give the Volume correction factors (VCF) to find the volumes at temperature for which the density is given.

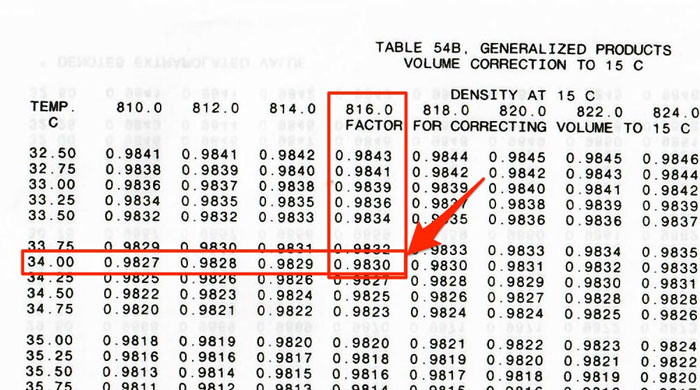

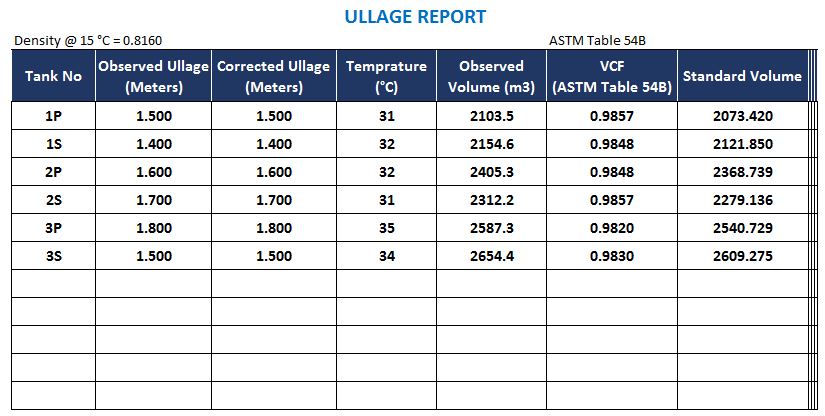

Let us say cargo surveyor provided the density at 15 deg C as 0.816 and ASTM table 54B to be used.

Let us use the same volumes and temperatures that we have used in our initial example.

So first we need to find the VCF from ASTM table 54 for temperature 34 Deg C.

Go to ASTM table 54 and look under density@15 C of 816.0 and temperature 34.0 Deg C.

So as we can see for temperature 34 Deg C, the volume correction factor is 0.9830.

Similarly, we need to find the VCF for cargo temperatures of other tanks.

And when the VCF is applied to the volumes at observed temperature, we get the volumes at 15 Deg C which is also called “Standard Volume”.

Here is how the ullage report would look like so far.

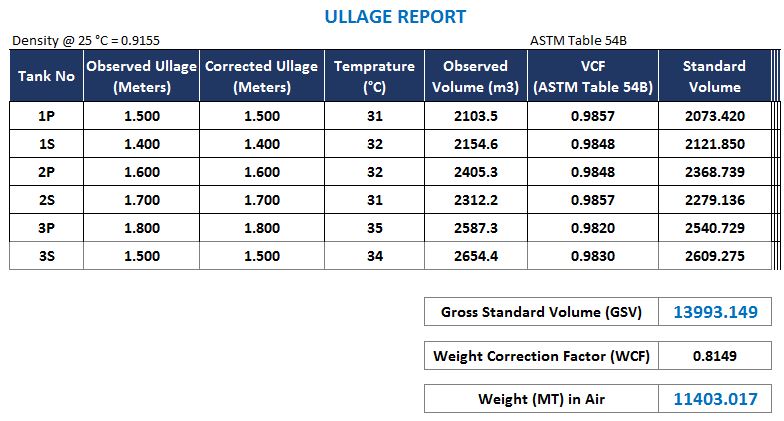

Now at many places may be using the standard volume instead of weight. The standard volume of the cargo would also remain same as this is the volume at the fixed temperature (15 Deg C).

But in any case, we still need the weight of the cargo as the stability calculations need the weight of the cargo in each tank and not the standard volume.

Getting the weight from standard volume is simple. We have the volume at 15 Deg C and we have the density at 15 Deg C.

If we multiply these two, we get the weight by a simple formula.

But wait.

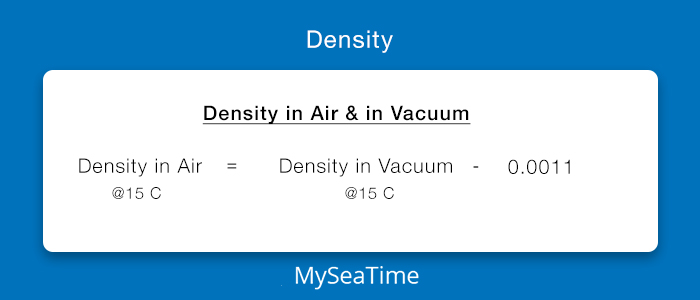

The density at 15 Deg C is always the density in Vacuum. So if simply multiply this density with standard volume, we get the weight in Vacuum.

So we then need to either convert the weight in vacuum to weight in the air as we discussed earlier or we can simply convert the density in Vacuum to density in Air.

There is a simple co-relation between density in vacuum and density in the air.

And we call this as weight correction factor (WCF).

So in our case, the WCF would be: 0.8149.

When we apply this WCF to the standard volume, we get the weight of cargo in Air.

In above ullage report, I have applied the WCF to the Gross standard volume but we can easily make one additional column and apply the WCF to the standard volume of each tank to get the weight in the air for each tank.

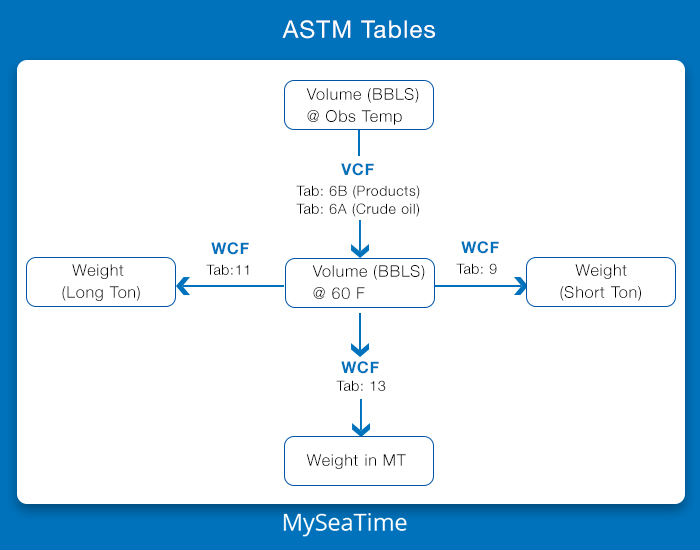

4. API Gravity at 60 Deg F and ASTM Table to use

Ports like those in the US do not use the metric system and hence do not use density.

Instead these port use API gravity at 60 Deg F.

And as you might have guessed correctly, these ports also do not measure the temperature in Deg C but in Deg F.

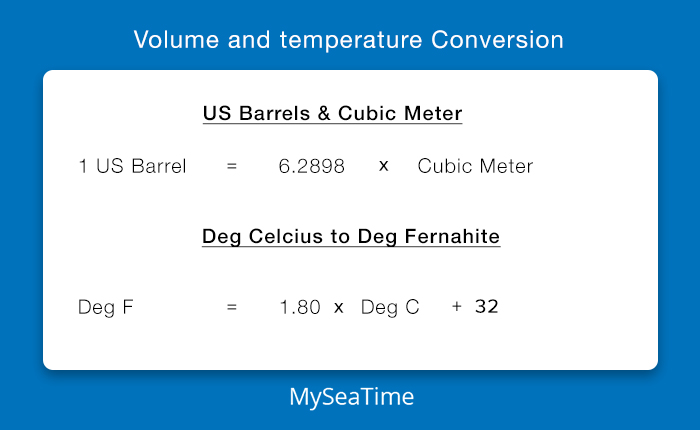

Also, the volume is measured in Barrels and not in cubic meters.

So when in these ports, we need to have the volumes in Barrels and temperature in Deg F.

This is not so difficult a task. There is a simple formula to convert these.

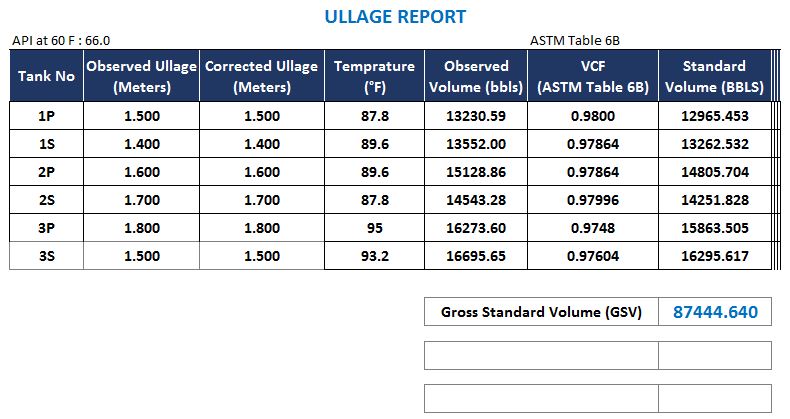

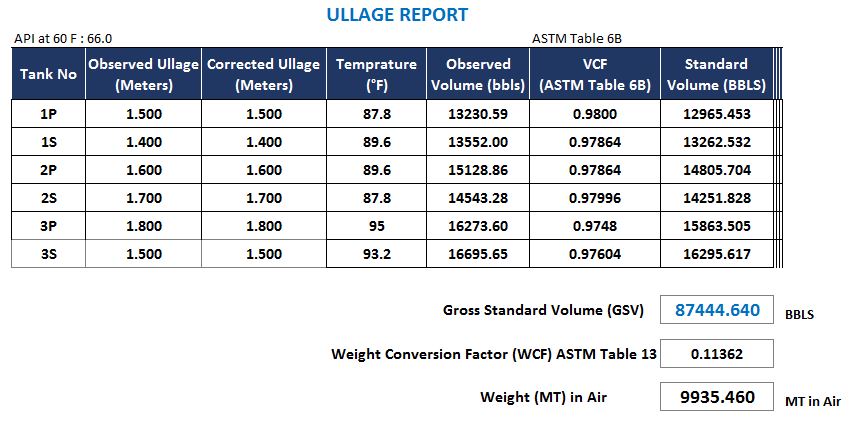

So for these ports here is what the volumes and temperatures in ullage report would look like.

Following the same principle as earlier, we need to bring this volume to volume at 60 Deg F.

And to do that we need to apply the volume correction factor.

We need to use a table that we can enter with provided API gravity at 60 Deg F and observed temperature in the tank to get the VCF (Volume correction factor).

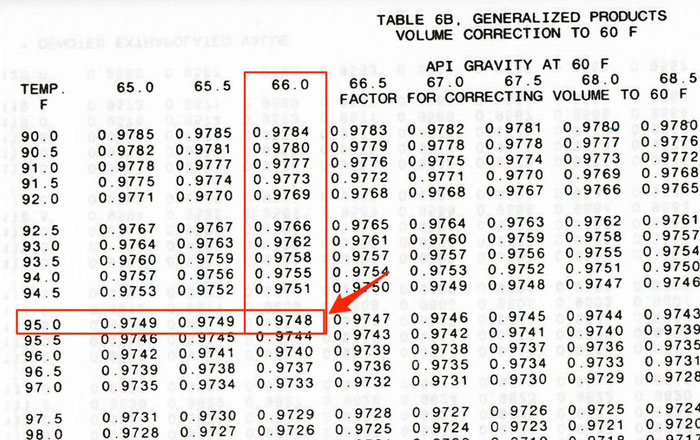

This the ASTM Table 6B.

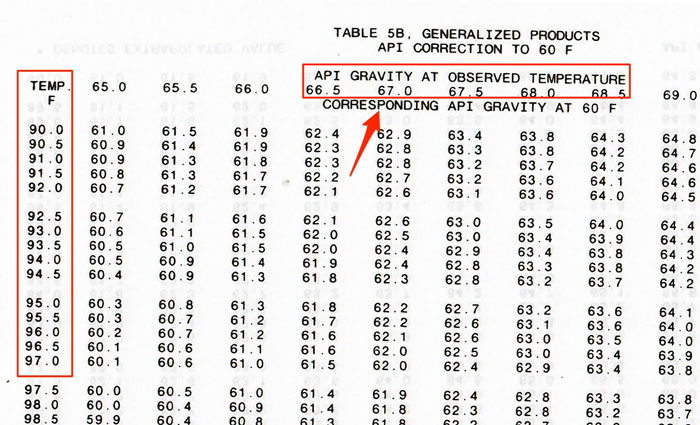

Let us say the cargo surveyor has provided the API gravity at 60 F to be 66.0

Let us find the VCF for temperature 95 Deg F.

As we can see from table 6B, the volume correction factor for API at 60 Deg F of 66.0 and temperature 95 Deg F is 0.9748.

Of course, if the temperature or API is between the two values listed in ASTM Table 6B, we need to interpolate to get the correct VCF.

Ok. So, in the same manner, we get the VCF (Volume correction factor) for other required temperatures that we have measured in each tank.

And when we multiply the volume at observed temperature with VCF, we get the standard volume, this time the volume at 60 Deg F.

We need to apply Weight correction factor (WCF) to the standard volume to get the weight of the cargo.

There are different ASTM tables to get the WCF for the known API at 60 Deg F.

- ASTM Tabel 9: To get the WCF to convert Barrels at 60 Deg F to Short Ton in the air.

- ASTM Table 11: To get the WCF to convert Barrels at 60 Deg F to Long Ton in the air.

- ASTM Table 13: To get the WCF to convert Barrels at 60 Deg F to Metric Ton in the air.

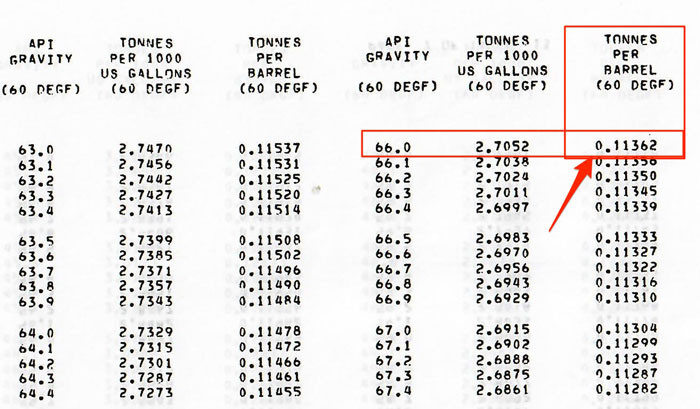

Let us say we are interested in calculating the weight in Metric Tons in the air.

In this case, we will use ASTM Table 13 to get the weight correction factor (WCF).

So in the ASTM table, look for the API gravity 66 and find out the WCF (which is given as Tonnes per Barrels).

So as we found out the weight conversion factor for API 66 is 0.11362.

We can apply this WCF to the standard volume to get the weight of cargo in the air.

Now the final ullage report will look like this.

Other ASTM Tables

So far we know that we need to use ASTM table 54 (54A for crude oils and 54B for products) for VCF and table 56 for WCF when we have been provided with density at 15 C.

And In Port like US where API gravity at 60 F is provided, we need to use ASTM Table 6 (6A for crude oils and 6B for products) for VCF.

And ASTM tables 9, 11 or 13 for WCG.

But there are other ASTM tables that supplement these tables that we discussed so far.

For example, to calculate the weight of the cargo with ASTM table 6 (6A or 6B), we need to have API gravity at 60F provided to us.

But what if we are provided with API gravity at some other temperature, say at 80 deg F?

Then there is ASTM table 5 (5A for crude oils and 5B for products) that can be used to convert API at any temperature to API at 60 Deg F.

Similarly, ASTM table 53 (53A for crude oils and 53B for products) can be used to convert density at some temperature to the density at 15 Deg C.

Ohh!!! And what if you load a cargo from US where API Gravity at 60 Deg F is used and to discharge this cargo at a port where they want to use Density at 15 Deg C.

Well, there is ASTM table 3 for converting API at 60 Deg F to Density at 15 Deg C.

While the ASTM tables that we discussed in previous sections are the one that is used mostly, there are other ASTM tables that supplement these main tables.

And even for the main ASTM tables, the information about which table need to be used for cargo calculation is provided by cargo surveyor.

We need to follow the information provided by the cargo surveyor because that would be the table that is used for shore calculations and we need to use the same to avoid ship shore quantity difference.

Conclusion

Cargo calculations are sometimes tricky.

Not because these are difficult but because there are so many variations to it.

But we need to understand that at the very basic level, we calculate the volume from ullage tables and we need to be provided with density at the same temperature as the cargo.

We multiply both and we get the weight of the cargo.

But for oil cargoes, we are either provided with density at 15 C or API at 60 F.

In this case, we need to get the volume correction factor (VCF) to convert the volume at the observed temperature to the standard volume which is volume at 15 Deg C or Volume at 60 F respectively.

We then need to apply the weight correction factor (WCF) to convert the standard volume to weight.

Different ASTM tables provide the value for VCF and for WCF.

There are different ASTM tables for crude oil and for product oils.

The one with letter A is for crude oils and the one with letter B is for product oil. ASTM tables without any letter are common for both crude oils and product oils.

Get your hands on ASTM tables and you will find that cargo calculations are not as difficult as it seems.

Share this:

About Capt Rajeev Jassal

Capt. Rajeev Jassal has sailed for over 24 years mainly on crude oil, product and chemical tankers. He holds MBA in shipping & Logistics degree from London. He has done extensive research on quantitatively measuring Safety culture onboard and safety climate ashore which he believes is the most important element for safer shipping.

Search Blog

152 Comments

Thank you sir, for explaining complicated topics in such a lucid manner, its an art ...

Thanks Anthony...

Hi Rajeev. Its seems to very hard to get correct excel formula to calculate correct VCF ASTM Tab 54A. I have crue oil density 0,9616 and 42, 25 degC and VCF should be 0,98214 but my formula gives much less. DO you have a correct formula to calculate correct VCF. In my formula I have a factor 613,97226. Is this correct? My email: mattijnasi@gmail.com

You can see www.petrocalculator.com, they provide latest standard as per 2004 to calculate standard density and VCF, Since all ASTM table given as per 1980 standard is old now. You have to follow 2004 standard.

Really useful!! Many thanks!

Glad you found it useful Boris...

Very nicely explained sir. Thank you very much for your kind effort for explaining cargo calculation in a very simple language.

Thanks Amit...

this information is very helpful for us master / tanker officers .. Pls next how to calculate : Vapour weight in LPG....Thanks, Capt. Rajeev Jassal.

Glad you found it helful Jorge.. Will try to write on similar topic for LPG.

very good Capt. Rajeev Jassal Thanks

Thanks Carlos...

very useful..many thanks Sir,

Glad you found it useful..

first of all, thanks for the explanation . but what i wanna ask u is .. does the air buoyancy exist? it sounds silly but it's hard to understand the concept of air buoyancy . my question roots from the cargo calcualtion report from our lab . there is two different figures for the same LNG cargo, M/T(Vac), M/T(air). i thought how weight of the same cargo chage with conditions such as vac, air , other than gravity. and i read ur article and still i'm like ... really? air buoyancy?? even in the tank??? so if u don't mind , could you elaborate this part or give me some examples?

Yes.. Air buoyancy do exists...It is same as how the same ship would weigh more in waters of different densities...each medium (including. Aur) offered some resistance and thus the buoyancy..

Good day Capt. Rajeev, Above well explained. Just wanted to know one thing how calculations are performed on chemical tankers. Different manufacturer may have different densities for same chemical. This is true especially for vegetable oils (Correct me if I am wrong). So how these calculations are performed on chemical tankers???There are no standard tables for chemicals.

For most chemicals.. the density table is provided by load port surveyor.. this density table have the densities for each degree of temperature.. the density of temperatures in decimal places is calculated by interpolations... as you right said, densities for the same chemical from different manufacturers usually change differently with change in temperatures, so we do not have anything like API tables for chemicals.

Hello, How are you ? Can you send me the format in EXCEL of working ship GM. Thanks a lot

Sir, when finding VCF from table 54B, the density to be used should be in Air or Vacuum?

Density in vacuum

All of your blogs did a vast contribution to pass my orals exam from uk in my first attempt...Thank you verymuch sir

Glad to hear that Krishna...

Really helpful sir, I am preparing for Ch Mates phase I exams ans as I am from a dry cargo background, this artice really helped me out. Thank you so much for sharing your knowledge in such a simple manner.

Glad you found it useful Sarath...

Thankyou sir , very well explained in simple words with deep explanation. This is the reason "Albert Einstein Quotes. If you can't explain it simply, you don't understand it well enough"

Thanks Bharat... and that’s one of my fav quotes too..

Your work is greatly appreciated, Sir! Thanks! wish u healthy and happy!

Thanks Maik...

Appreciate your blog.

Thanks Ahsanul...

Fyi after loaded 12964.034 MT RBD Palm Olein at Belwan Port one of small tanker vessel draft F/8.90M A/8.90M and when she came at Chittagong Port made vessel trim F 8.10M Aft 9.10M but port pilotage requirement is 0.20M by stern trim. According to ullage at berth in Chittagong Port with draft F/8.10M & Aft 9.10M cargo found 12963.543 MT as same as load Port qty of 12964.034 MT. but after discharged into shore tank cargo found 12935.589MT i.e 27.954MT short than the berth ullage 12963.543 MT. Would you please comment how it can be possible to checked the shortage?

There could be many reasons such as the ship’s tank not calibrated well in the delivery yards.. slight bending of the bulkheads during the age of the ship and sometimes even the shore using the density that they got after analysis of cargo received in shore tanks. Irrespective of the reasons, vessel is not concerned about how much cargo shore received. Ship goes by the figure on the ship and on any protest presented to the vessel, vessel must remark it as “for receipt only, vessel not responsible for anything beyond ship’s rail”.

This Is how to explain ...god bless you sir ..everything we need to know and how to apply you have explained in such a way .thanks a lot sir thanks a lot.

Thanks Nandan...

Fantastic. As expected, very well explained. Thank you sir for help us junior officers to further our knowledge as aspiring Chief Officers.

Glad you found it helpful John...

was really clear and easy to understand ,thank you too much sir,

Thanks Abo...

thanks a ton sir.things have simplified now and better to understand

Glad to hear that Sachin...

Thanks for this knowledge and experience based article which I was searching for long time. Hope more articles on LPG and other products will be shared. Thanks once again.

Glad to hear that Casimer...

You can find information about different software for calculation of quantities for ship and shore side for Oil, LPG in Metric units and US customary units, for ship's side for LNG in metric units, for chemicals in Metric units, an oil blending program in Metric units and US customary units, a draft survey on the following websites: http://surveycalc.com and http://oilcalc.com All this software is based on the latest ASTM, ISO and API standards.

Do we have to use same procedure for to calculate loadable quantity. At once we receive commence new charter.

Loadable quantity is calculated by deadweight calculation. There is no need of use of ASTM tables for that...

May I know what is the complete name of the book use for calculating GSV at 20degC which they are using at Brazil?

Thank you.

Thanks Abdul...

Thank you sir for the explanation.

Thank you for reading Manish...

Thank you sir for boilng down the cargo calculation concept in very simple and easy format

Glad you found it useful Bhuvaneshwar...

Please write a detailed bolg on off course alarm and off heading alarm.

Will surely write on that Ujjwal...

Thanks Rajeev. If you have table astm 54b in arquive, please sent me.

This question is related to the cargo calculations problem in my last ship.I had 4 commingled cargoes(same grade :PFAD) in few tanks of my ship(Type II Chemical Tanker) from different shippers loaded at different ports and all of them had a very slight density difference .Once i reached next load ports i had a problem on what density to use as the commingled density will be different from density given by load port surveyor.Awaiting your kind response on that.Thanks

In this case, surveyors at each load port where cargo is commingled has to provide 2 density tables. One for the cargo loaded at that port and second for commingled cargo...At discharge port we have to use final density table of the commingled cargo...

What is the difference between density correction factor and temperature correction factor??.I saw these two inputs given in my loadicator !!Are they same and if not why separate inputs given for weight calculations!!

Thank you Capt. Kassala. Would you please confirm the understanding of weight and mass to perfect this fantastic article. Unit of mass is Kg/metric ton/lb, while unit of weight is Newton/lbg. Mass = density * volume, while weight = mass * gravity I believe when you explain about the weight in air / weight in vacuum, the density in table 56 a kind of corresponding density such that when the corresponding mass times gravity 9.81 could give the weight in air/vacuum Appreciate you hard work and sharing of knowledge

Thank you very much Sir, providing an extremely helpful article for every one involved in Petroleum sector .

Let me share on my face book sir.

I am very thankful to you respected sir for giving us such a good knowledge about tanker cargo operations. Sir I need your help to get solved some tanker numericals, as I only sailed on container ships I'm very much interested in these topics. So kindly please help me to do so. Awaiting for your valuable suggestions. Sir pls reply me on same email id which is provided. Thanking you Shivam

Sir can you pls tell me step by step answer for the following question pls. I will be thankful to you. Q1. A tank measuring 21m*15m*16m has an ullage port extending 1 m above the top of tank. It is to be loaded with crude oil at 23°C. 3% of the tank vol. is to be left for expansion when maximum temperature expected during the outage is 42°C. ( Density of oil =0.81@ 15°C in vaccum). Find the mass of oil loaded and ullage at load port. Given From ASTM tables- VRF for 23°C = 0.9929, VRF for 42°C = 0.9761, WRF = 0.81 - 0.0011 = 0.8089 Sir pls solve this question step by step as it would be great help for me. Awaiting for your reply. Thanking you Shivam Singh

thank's a lot for the valuble information.I Would like to know how to find Reference temperature for LNG cargo if pressure relief valve set at 25KPaG +10%. Supposed that atmospheric pressure is the max ;pressure of atmospheric pressure range 104KPaA. Reference temperature to calculate max filling limit with practical exemple? For LNG not LPG

Can someone explain my How concert MT Air in to MT Vac

isn't MT a mass measurement hence, it will be the same whether @ ambient or @ vacuum environment

I mean How to convert*

Hi, thanks for this detailed article. Would just like to ask how you would go about measuring the BL figures for lightering/ship-to-ship operations.

Great article sir....i have been following your blog since 3-4 years, every thing is written so nice and so easy to understand, and with detailed explanation which otherwise can not be found anywhere else. Thank you very much sir...

Thank you Sir for a really good explanation.. but I have a doubt regarding the conversation of US bbl to cu.m that you have mentioned above.. is it correct?. .. can you please verify.!!

Very clearly explained, sir. But I would also like to know the calculation procedure which involves blending of two different cargoes of different density and temperature inside a tank.

Thank you sir, about astm 60A, where does it apply?

Great thanks to you .i would like to known whats the procedure to caiculate LPG vapour in fully pressure vessel ?

Excellent explanation

Very useful information.

Nice article sir. Very useful.

Thank you very much Captain.. I am from a Oil company and was boarding tankers for last few months and had a few confusions always. This blog answered a lot of them. Really appreciate your time into it. Keep it up sir.

Thanks alot

Dear Rajeev, Excellent work. I can understand the amount of time you have dedicated to transfer knowledge to others esp. some subjects like which is not taught in universities. My question to you is regarding the metric tons(air) and metric tons(vac). Air-bouyancy technically should affect only the weight, not mass. Since we are calculating from the volume and ullages in individual tank, we determine the mass (unit: tons) of the oil and not weight (Unit: Newton). In the calculations, we have not used explicitly any accelaration due to gravity (g) value of 9.8 ms^(-2). Mass should remain the same whether it is in vacuum or air? I am unable to wrap my head around this? Please help.

very well explained in simple words. If gauging reference hight changed(because contractor wants to change the existing radar so he needs to change the ref hight), Do I need to recalibrate the whole tank and establish new calibration table or not? Is partially calibration needed?

Nice article sir. Very useful. {One doubt, how to convert WEIGHT IN VAC. after we get WEIGHT IN AIR using ASTM Table 13: To get the WCF to convert Barrels at 60 Deg F to Metric Ton in the air? when API Gravity is used} Is it like using ASTM table 3 for converting API at 60 Deg F to Density at 15 Deg C. and thereafter using table 56 to get the factor.

Thanks for your detail informations regarding calculation.

how to study trim calculation on bunkering vessel. any reference available for this. i searched many sites but no books available. Please tell me the solution.

Charterer requested to make a max intake stowage plan based loading Gasoil S.G. 0.72, loaded temperature 33 deg C. For calcs I`ve entered in my loadicator Gasoil density in vac at 15deg as 0.72 and in the table with cargo tanks applied 33 deg for each loaded tank, having required volumes in m3 and in mt for preparing stowage plan . Were my calcs correctly made in this case? Thanks in advance!

Dear sir,pls give some information on wedge calculations on tankers. Thanks

Thanks sir... It was very useful..

Sr, God bless you, really, not everyone has the will to spend sometime to explain others, even on ships, thank you so much for all your articles!

Sr, God bless you, really, not everyone has the will to spend sometime to explain others, even on ships, thank you so much for all your articles!

Great, just correct the mistake in vol conversion part 1 cubic meter = 6.2898 x 1 US bbls

Sir good day Excellent job which table to calculation for chemical we r apply density temperature *tank temperature-1

Very valuable information. This will clear a lot of confusions for people attending exams as well as seagoing mates.

Sir good day, I used to be on board LPG, Product and Crude Oil. It is a great article and have no problem of following. However, my inquiry is for LPG. i am pretty sure on Saturated Hydro Carbons like propane and butane, density assigned is at 15 deg.....hence vcf is applied. My question is on Petro-ChemcLPG like Ethylene, Ammonia, etc where we used the densities per observed temp...so do we need to apply VCF for such cargoes? appreciate much if you can confirm which is which.

Good Morning Captain , i have one question. For asphalt/bitumen cargo we can use tables 53A to convert density to 15C?

Hi Captain , In Asphalt / Bitumen cargo , how can we convert relative density at 25C to Density at 15C? what table can we use? Waiting to hear from you both questions, thanks

Hi Captain, You have nicely explained the topic in very simplified way in such way that common man(12th with science) can understand easily. Hats off for explaining complicated topic in much simplified way.

Well explained Sir. Thank you

Thanks a million Mr. Rajeev for such a helpful information.

Hi Mr. Rajeev, When converting Cubic Meters To Metric Tons, Is it necessary to first standardize Cubic Meters to 15C and then convert to Metric Tons?

Volume and Density of oil both changes with the change in temperature. To convert Cubic Meters to Metric Tons, both of them should be at the same temperature. Lets say you load a cargo of oil in a tank at 30°C, then the volume of oil that you have in the tank is at 30°C. If you happen to know its density at 30°C then you can directly convert it to Metric Tons. But in tanker trade normally the density of the cargo is provided by the shore and it is at a standard temperature of 15°C or 60°F and that is the reason why we need to convert the volume of the cargo loaded to a standard temperature of 15°C or 60°F (by applying a Volume Correction Factor) before we can convert it to Metric Tons.

Total oil volume decreases with increase in temperature in floating roof storage tank and increases with decrease in temperature. kindly give clarification. and also what are the losses will be there in floating roof storage tank.

Dear Sir, very helpful your blog for learning thankyou. Sir, my request is that if possible can provide me the tutorial for the LPG tanker calculation ???

hello sir, u has explained so nicely. thank u for that. have some lil doubt. 1) when we are getting WCF from table 56 anyhow there is another thing that density in vacuum - 0.0011 to get density in air. can u explain from where did we get this value of 0.0011 y not other value. Thank u

THIS IS VERY HELPFUL SIR ! WHERE CAN I FIND ASTM TABLES 54A,54B AND 56.EMAIL-rickeyraj61@gmail.com

APP STORE AND PLAY STORE

Dear sir, its very helpfull to me. can you explain to me how to get gross weight and nett weight for petroleum cargo.....? Thank's

Great article and thanks a lot for sharing.

Thank you captain for the post. Could you elaborate on why densities are obtained at standard temperature of 15 degrees?

Hi everyone , i want ask you: How to change D15 to D35 (Density at 35 degress) ???, Help me please !. ex: i have D15 of Diesel Oil is: 0.8386 , so how to change this density to D35 (Density at 35 degress ) ?

Kindly please explain to us regarding to VCF with some formulas. And is it used for all grades of oil or changeable? Thank you so much.

Kindly please explain to us calculation of VCF and formulae. with some examples? And can use for all grades or changeable? Thankyou so much.

Sir, Very well explained in simple language...layman can also understand easily. Thanks for effort

Dear Sir, Kindly please give me the ammonia gas tanker survey calculation ....10 years before i have done the survey, now i forgot...if you have this, please send it to my email ...

Very very useful information thanks sir.

Total oil volume decreases with increase in temperature and increases with decrease in temperature. kindly give clarification. and also what are the losses will be there in floating roof storage tank.

how calibration is done for floating roof storage tank and by which method?

There are 4/5 methods to calibrate tank, detail given in API and ISO standard. At the time of calibration, floating roof weight find by weight as per fabricator given or water displacement calculation.

dear sir, pls give formula computation if vessel from dry dock ang vessel under nitrogen condition..how to compute the gas needed used for gass up operation in mt. if vessel in Lpg..

Im little confuse. If density in air @15 = density in vacuum@15 - 0.0011= 0.8149 how it become?

Grazie Captain!!! Great article! Thanks

Good day sir, Your articles are great.O have one douby. Where to find what is the minimum API cargo that can be loaded in a tanker

Thank you very much for more formation

Sunrise International has the finest international courier and cargo equipped with significant expertise and knowledge of the industry. We have an exceptionally well-trained and professional team that aids all our processes. Moreover, we are proficient in managing the varied requirements of our clients with utmost efficiency. You can rely on us for speed, dependability and assurance with your international courier and cargo services. Therefore, if you want the best courier and cargo in Mumbai as well as internationally, Sunrise International can be the best choice.

Good day capt, Your articles are read by seafarers world wide and it helps us a lot. I had a request of you could write a detailed article on cargo calculations of a lpg/lng tanker that a chief mate needs to know. It would be of great help Best regards.

Dear Sir, you have Table VCF for calculation LNG and method to calculate? Pls, Help!

1 cubic metre = 6.28 US Barrel

It is easier than i thought. thank you for the explanation sir. cheers

thank's capt , really it's very interesting explanation. help me a lot in my final study project "asphalt cargo calculation" at chemical tanker

Hi to everybody, please advice with calculations in Russia & Brasil. How it's often became, the density of cargoes there given by 20°C , but need calculation with 15°c , for port of discharging.

Thanks for this. I'll love you to also do a tutorial on how to calculate LPG volumes; in litres and weight

Thanks a lot sir for posting such informative articles in your blog. Apart from what i learned in college , its your article which is simple and precise which made me gain more knowledge regarding any matter, may it be sextant or cargo calculation . Thank you for being a great teacher

According to Value Market Research, the latest technology trends and global market opportunity analysis in the Bitumen Market industry growing with a high CAGR in the upcoming year. Our report has categorized the market based on technology, service, development, vertical and region. https://www.valuemarketresearch.com/report/bitumen-market

Good day sir, Kindly advise me on ANP table for crude calculation. Tnx

hello, thanks guy good information, somebody has table 21 and 23? please

Nice Info..., Bitumen Manufacturers

Nice Information ,,,.... https://www.petraoilbitumen.com/

Kodus Capt Rajeev, Pls. Continue making articles like this. alot of aspiring officers are rooting for you... If You have extra time, Maybe About "Basics of making stowage Plan" for tankers.hehehe

Thanks for sharing your knowlwdge. It has been wonderful taking my time going through. So much great taste

Hi sir! Could you please explain where VEF comes into play when doing the calculations. Secondly, what if the surveyor is providing the vessel with a density at a temp other than 15deg C.

Good day Sir, kindly advise me on VCF formula. If observed density is 0.721 observed temperature temperature 20° C and corresponding density 15° C with 0.7251. how can correct VCF=0.00117. Just give me the VCF formula.

A cup is equal to 0.23636 liters, so if you have one cup then you have 236 ml or roughly 237 milliliters of liquid. HOW MANY CUPS IN A LITER? visit this.

Finally feel confident after read above.Thanks a ton sir for such nice explanation.

Thank you sir for sharing these greatest informotions ,really it was a ressource that i'm search.

Thank you for such a great article. Pls confirm the , equation given for meter cube to us barrels Thank you once again. I had an opportunity to sail with you in Chembulk Houston.

You tackle issues and challenges with a positive, can-do attitude. I highly recommend you RKDEMY for diploma engineering coaching classes Visit- www.rkdemy.com THANK YOU

Leave Comment

More things to do on myseatime

MySeaTime Blogs

Learn the difficult concepts of sailing described in a easy and story-telling way. These detailed and well researched articles provides value reading for all ranks.

Seafarers Question Answers

Ask or answer a question on this forum. Knowledge dies if it remains in our head. Share your knowledge by writing answers to the question

MySeaTime Podcast

This podcast on the maritime matters will provide value to the listeners. Short, crisp and full of value. Stay tuned for this section.

Great article sir. Thanks for sharing ur knowledge. More power Sir! Always waiting for more articles.

Glad you liked it Ivan...

Sir, could you please explain how should I use ASTM Table 54C for getting ethanol density corrected to 15C?

Great Learning which you have provided. Respect goes to you sir. one thing is confusing again that we simply multiply corrected volume with density at 15C (which is definitely measured in air and not in cacuum) to have weight, so why we are considering vacuum to air conversion. Please guide. Thank you

Great Learning which you have provided. Respect goes to you sir. one thing is confusing again that we simply multiply corrected volume with density at 15C (which is definitely measured in air and not in vacuum) to have weight, so why we are considering vacuum to air conversion. Please guide. Thank you

knowledge is power, so you have empowered me by sharing your knowledge with not just me but whom ever seek it. Many thanks

Dear Rajeev, appreciate if you could help me in the below request: I need an excel where I could convert the meter cubic from the gas meter of Butane or Propane to liters, where i have gas meters installed in building for tenants and i supply the gas by liters in their main tank, and when i want to invoice them they need the invoice in cubic meter not liters, so I should do the conversion according to pressure, density and temperature. Also if you have excel for conversion liters to weight in MT or vice versa according also to pressure, temperature and density. Thank you in advance