The way ships are maintained has changed since last decade or two.

Rarely will it happen that a seafarer completes his contract without the ship going through any survey or inspection.

It is now surveys and inspections all the way.

We have one or more surveys and inspections to cover each element of the ship.

For example, surveys for safety equipment certificate ensures that ship’s safety equipments are maintained in the way these should be.

Safety construction, load line certificate surveys deal with the construction part of the ship.

So where does “Enhanced survey programme” fit in all this and why do we have this?

To understand that let us briefly go to the history of the enhanced survey programme.

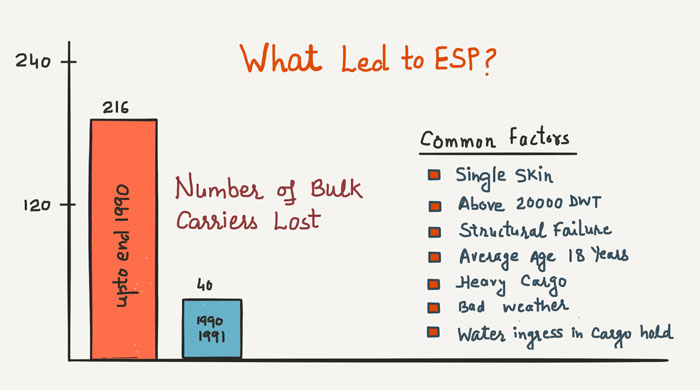

Why Enhanced Survey Programme?

The Enhanced survey programme is applicable for bulk carriers and oil tankers.

Definitely, IMO found something grossly wrong with these ships. Something so wrong that they had to bring more stringent regulation for these type of ships.

Here is what was wrong.

So many ships and lives lost !!! All because something was wrong with either the design of the ship or with the maintenance of the ship.

During this period, the number of oil tankers lost may not be as many as bulk carriers but oil tankers were included for the requirements of ESP because of cargo these carry.

Following these incidents, more and more P&I clubs started to question the quality of surveys done by the classification societies.

In 1993, IACS introduced Enhanced survey program for more close up inspections of these ships.

But then again In 1994 alone, 12 bulk carriers were lost in the sea.

This made the IMO to take special measures and to adopt a new SOLAS chapter (Chapter XI-1) to enhance maritime safety.

Among other requirements, this new chapter required bulk carriers and oil tankers to go through enhanced survey program.

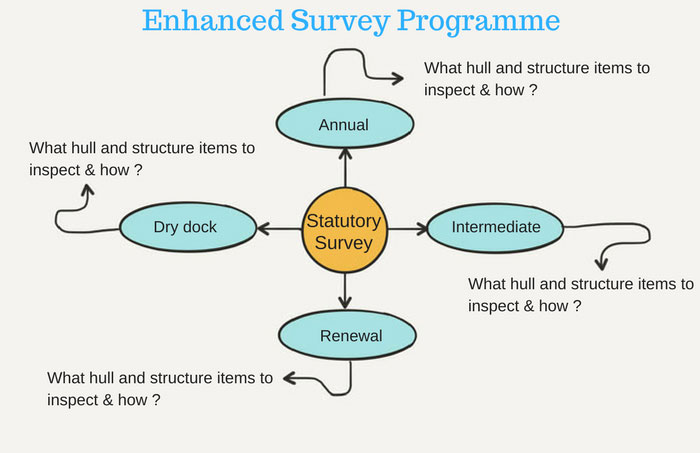

What is Enhanced survey programme

A ship undergoes four type of surveys during its 5 yearly cycle of statutory surveys.

- Annual Survey

- Intermediate survey

- Renewal Survey

- Dry dock survey

So where does Enhanced survey programme fit in these?

Enhanced survey programme is not a separate survey. ESP just gives the specific guidelines about what to inspect during these surveys with respect to hull and structure of bulk carriers and oil tankers.

These detailed guidelines are given in the ESP code.

Let me give you a brief about these guidelines.

Who to inspect

- For bulk carriers of 20,000 tons deadweight and above, two surveyors should jointly carry out the first scheduled renewal survey after the bulk carrier passes 10 years of age (i.e. third renewal survey), and all subsequent renewal surveys and intermediate surveys.

- On bulk carriers of 100,000 tons deadweight and above, the intermediate survey between 10 and 15 years of age should be performed by two surveyors.

When to inspect

- The renewal survey may be commenced at the fourth annual survey and be progressed during the succeeding year with a view to completion by the fifth-anniversary date.

- A survey in dry-dock should be a part of the renewal survey. There should be a minimum of two inspections of the outside of the ship’s bottom during the five-year period of the certificate. In all cases, the maximum interval between bottom inspections should not exceed 36 months

How to inspect

- For ships of 15 years of age and over, inspection of the outside of the ship’s bottom should be carried out with the ship in dry-dock. For ships of less than 15 years of age, alternate inspections of the ship’s bottom not conducted in conjunction with the renewal survey may be carried out with the ship afloat.

- In any kind of survey, i.e. renewal, intermediate, annual or other surveys having the scope of the foregoing ones, thickness measurements of structures in areas where close-up surveys are required should be carried out simultaneously with close-up surveys

I have just given a couple of bullet points about what these guidelines are.

If you get your hands on ESP code, you will see that these guidelines provide much more details than this.

It covers the minimum requirements for the inspection of ship’s hull and structure during each type of survey. The structures like

- Cargo holds and hatch covers

- All pipings

- Ballast tanks

- All Hull plating

- Watertight bulkheads

It also guides about the extent the inspection (overall survey or close up survey) for each of these elements during these surveys.

The overall survey is intended to report the overall condition of the hull structure. For example, as per ESP code during the annual surveys, the overall survey of the cargo tanks need to be carried out.

This would mean that surveyor needs to do the good visual inspection of the cargo hold.

Close up survey is a survey where the details of structural components are within the close visual inspection range of the surveyor, i.e. normally within reach of hand.

Again as per ESP code, a Close-up survey of cargo holds is required during renewal survey. So during renewal survey, each part of cargo hold need to be in hand reach range of the surveyor.

So shipowner may need to arrange for scaffolding in the cargo holds.

Now that we know few things about ESP, let us understand the process involved in the ESP.

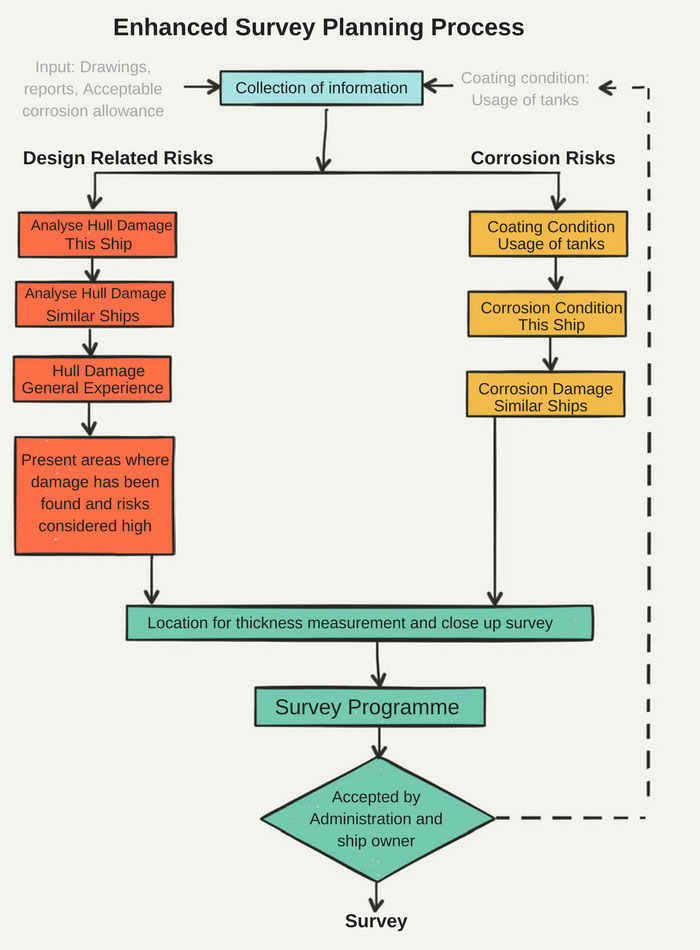

1. Survey Programme

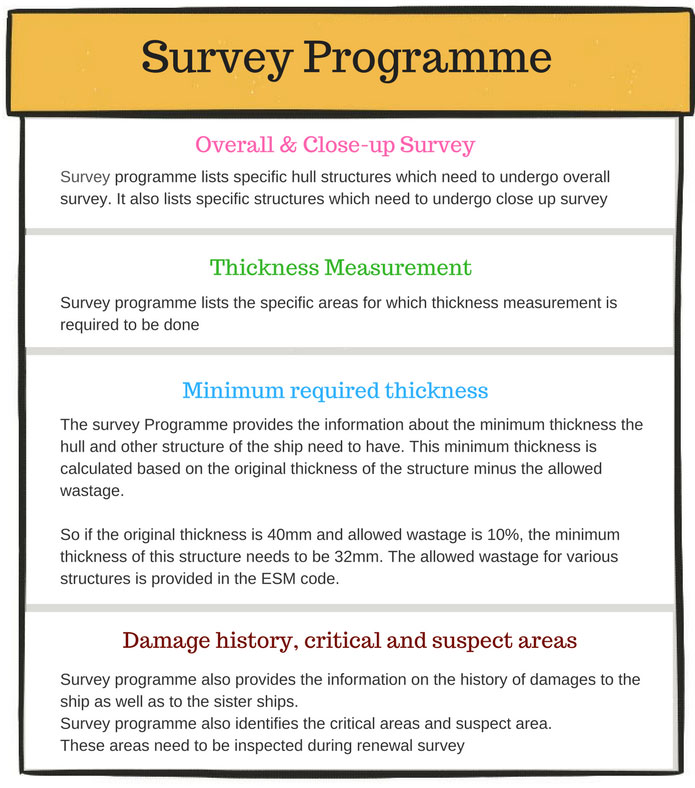

ESP code requires that a survey programme is developed before the renewal survey.

The survey programme document gives the complete detail of what needs to be inspected and what resources are required to conduct the survey.

Survey programme gives the inspecting surveyor a written plan to follow.

Survey programme is sometimes also called “Survey planning document”.

The purpose of this planning document is to identify the hull related critical areas that must be inspected during the renewal survey of the ship.

But how these critical areas are identified? These few resources help in identifying these critical areas.

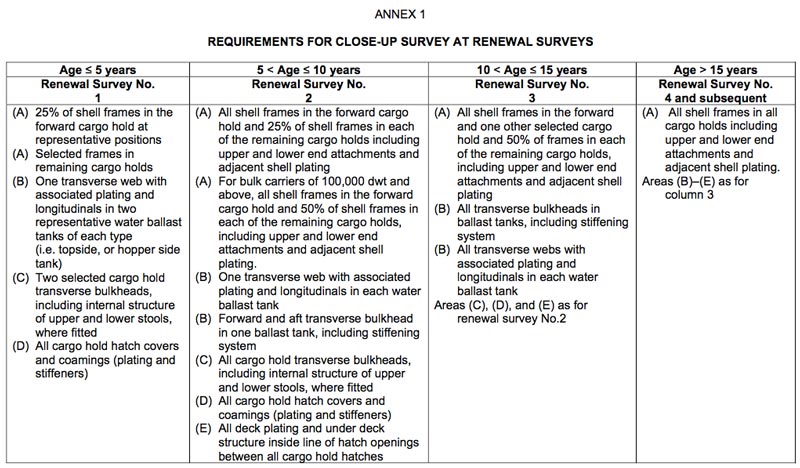

i) ESP Code

ESP code has detailed instruction on the minimum criteria for inspection during each of the statutory survey.

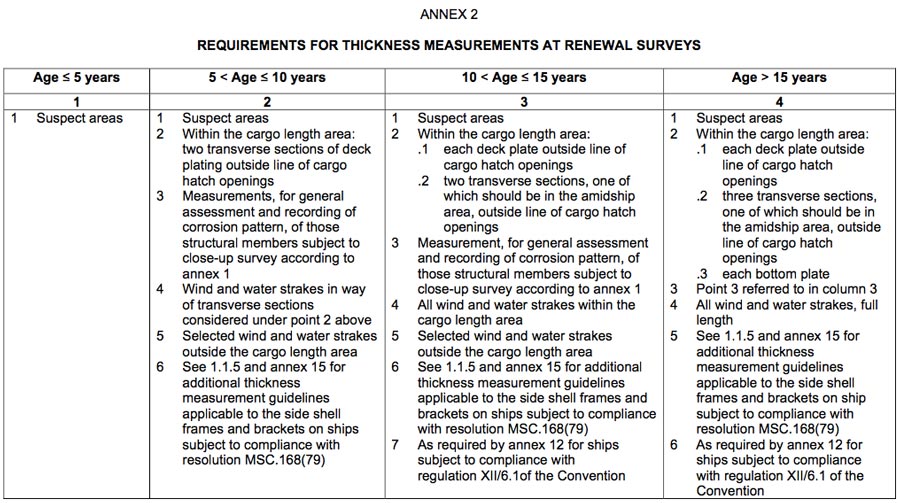

For example, Annex 1 of the ESP code defines the requirements for the close-up survey during renewal survey of the ship.

Similarly, Annex 2 of the ESP code defines the requirements for the thickness measurement during renewal survey of the ship.

So the guidelines given in the ESP code becomes the first resource on the basis of what “Survey programme” or “Survey planning document” is developed.

ii) Survey planning Questionnaire

Before survey programme is developed, the ship owner is required to complete a survey planning questionnaire.

Ship owner is supposed to provide information on

- Any hull related deficiencies identified during PSC inspections of the ship

- Any hull related non-conformities issued during SMS audits

- Cargo carried history of the ship to get the information on how frequently corrosive cargoes are carried that has the potential to damage the coating.

- The condition of the coating as per the ship owners inspection of the ship spaces.

The ship owner’s response on this questionnaire is considered while developing the survey programme for the ship.

For example, if in the survey planning questionnaire it is noted that cargo hold #1 has carried high sulphur coal very frequently, this hold may be subjected to more strict inspection.

In this case, survey programme would include more areas for a close-up inspection and thickness measurement of cargo hold # 1, above the minimum requirements of ESP code.

iii) Damage history

There is this one last information that is taken into account while developing the survey programme for the ship.

This is damage history.

Not only for the ship in question but also for the sister ships.

If the ship or its sister ships have suffered frequent damage of one particular area, that area is identified for more close up inspection during the renewal survey.

iv) General damage trends in the industry

Survey programme also takes into account general ship damage trends in the industry.

For example, let us say in short span of time a number of bulk carriers have sunk because of cracks at the midship area.

The more close up inspection and thickness measurement (over and above the minimum requirements as per ESP code) will be included in the survey programme.

v) Critical areas and suspect areas

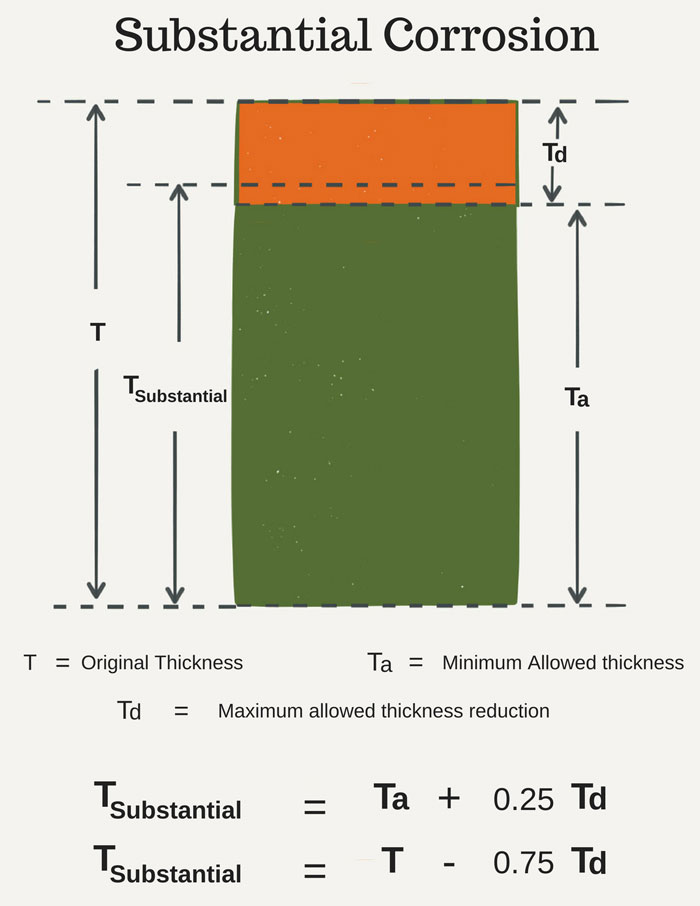

Survey programme takes into account any critical areas and suspect areas. These areas are identified from the previous inspections or previous thickness measurement reports.

For example during previous renewal survey, if certain areas are identified as having substantial corrosion, these areas will be considered as suspect areas.

Once all the data is available, a specific survey programme is developed for the ship.

2. Survey planning meeting

Once survey programme is established, it is time for executing the survey programme.

Survey planning meeting is the first step in executing the survey programme.

Survey planning meeting is held before the renewal or intermediate survey is commenced. As the renewal survey is carried out during dry docking of the ship, this meeting will be carried out just before the dry dock.

This meeting is between the attending class surveyors, ship owners, and master/chief engineer of the ship and thickness measurement company.

The main agenda of this meeting is to discuss the

- Schedule of the ship

- execution of thickness measurement, such as when the holds/tanks will be ready for thickness measurement.

- the extent of close up survey

In short, the content of the survey programme becomes the agenda for discussion in the survey planning meeting.

3. Conducting the survey

After the survey planning meeting, the survey is carried out as agreed and as per survey programme and minutes of survey planning meeting.

Thickness measurement company will carry out the thickness measurement of the agreed areas.

The person carrying out the thickness measurement will usually highlight any structure related concern he finds while carrying the UT gauging to the class surveyor and the ship owner’s representative (usually superintendent).

Based on this, the class surveyor may extend the scope of thickness measurement.

4. Survey Reporting

Once the survey is complete, it is time for creating the report for the survey that will show the summary of all the surveys done and its outcome.

The reports that need to be generated are

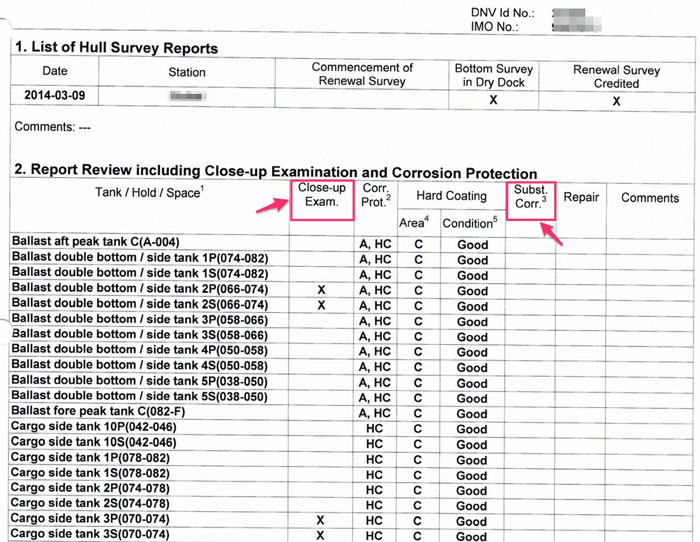

Condition evaluation report

As the name suggests, this report gives the complete report of the renewal survey conducted for the ship.

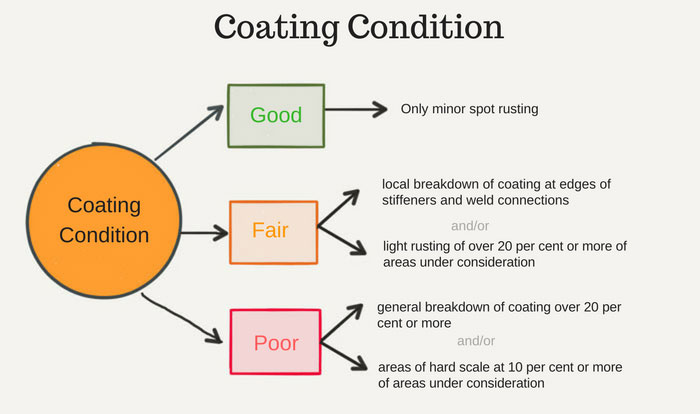

For example, it would give the actual condition of the tank coating.

As per the ESP code, the condition of the tank coating need to be defined as any one of these

- Good

- Fair

- Poor

If a condition of class is issued to the ship as a result of renewal survey, the details of the condition of class will also be provided in the condition evaluation report.

Condition evaluation report would also have the details of any memorandum of class issued to the ship.

Condition evaluation report also documents and highlights any area that has been observed to have “substantial corrosion”.

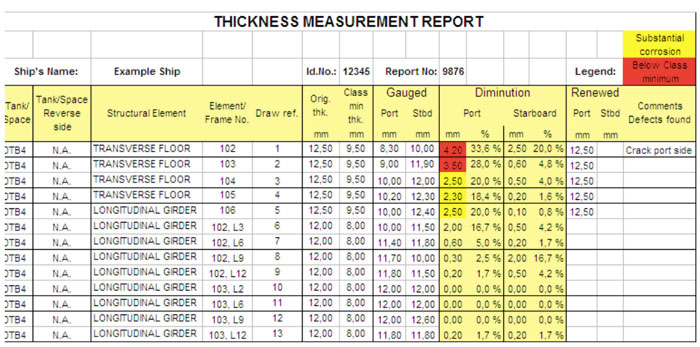

Thickness measurement report

Condition evaluation report will provide the summary of thickness gauging report and any area of concerns identified in thickness measurement.

But we also need to have the complete thickness measurement report with all the measured readings of the hull structure and tanks.

This thickness report is required to be sent to the flag state.

What ship staff need to know about ESP

And now the most important question. What exactly ship staff need to know about ESP?

First, ship staff needs to know what all inspections and surveys are required to be done as per ESP.

This we already discussed so far in this post.

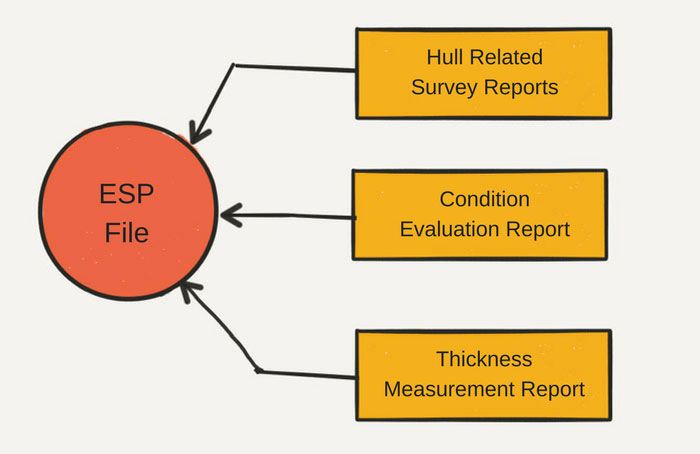

But the most importantly, ships staff need to maintain an ESP file on board.

This file will have

- Survey reports related to hull structures

- Condition evaluation report

- Thickness measurement report

Master has to make sure that these records are available in the ESP file.

After the renewal survey, it takes some time for ship’s classification society to prepare condition evaluation report.

So condition evaluation report may arrive on board after one month from the completion of renewal survey.

During any inspections, the master must be able to convey this fact to the inspectors who may want to have a look at the condition evaluation report.

Same may be the case with thickness measurement report.

Master and the chief officer must understand the content of “condition evaluation report”.

They must know if any areas with “substantial corrosion” are identified in the condition evaluation report.

Also, they must know if any tank coating has been graded as “Fair” or “poor”.

Whenever ship staff is making the routine inspection of these sections of hull structure, particular attention must then be given to the areas identified to have substantial corrosion or with tank coating as “Fair” and “poor”.

Conclusion

The voyage of a ship is called an adventure because it is a risky environment.

These risks are found to be even higher for the Bulk carriers and tankers.

These risks increase many fold if the hull and structures of these ships are not maintained absolutely good condition.

Enhanced survey programme gives the specific guidelines for the inspection of hull related items during statutory surveys.

ESP has ensured these ships are maintained in a way that ensures the safety of the bulk carriers and tankers.

Share this:

About Capt Rajeev Jassal

Capt. Rajeev Jassal has sailed for over 24 years mainly on crude oil, product and chemical tankers. He holds MBA in shipping & Logistics degree from London. He has done extensive research on quantitatively measuring Safety culture onboard and safety climate ashore which he believes is the most important element for safer shipping.

Search Blog

32 Comments

Sir kindly advise who makes Survey planning document, is it Class or Owner, and when is it made before 4th anniversary or at yard during build, TIA , pls do write on CAP/CAS also when u get time.

It is the responsibility of the owners/manager to prepare the survey planning document but in reality class of the ship helps the owners/managers to prepare this. It is prepared/submitted around 6 months prior to the special survey (5 yearly).

I love your work...... its easy to comprehend rather than reading the whole ESP...

Thank you Sanjith... I am glad that you liked it...

Good day sir, Can you please confirm if the ESP code applies to Bulk carriers and tankers of what age ?

As the ESP code is for surveys during the renewal surveys of the ship, it becomes application when the vessel is 5 years old (When the ship goes for its first renewal survey)

Thanks for the detailed explanation, Good job!

Thanks Ramon...

So for a second engineer, his main duty will be to make the pipeline and tanks ready for thickness measurement. right ? Does engine room Double Bottom tanks come under ESP ?

Excellent Article Sir, if you get time, please do write about CAS & CAP Survey too. Thks.

Sir, great work, could you please provide some info regarding how to differentiate enhanced survey and enhanced safety?. Thank You

Thank you very much for the detailed explanation. It is easy to comprehend. I really like reading your articles. It helps me a lot.

Glad you liked it Bindong...

What is the meaning of "record of last UT readily available in construction file"?? can you help me please.

This refers to the thickness measurement report. Last Thickness measurement report (UT gauging) should be available in the ESP file.

Sir, very good article on ESP. I have been asked to attend on a 29 year old RORO vessel for renewal survey programme. I know this is not subject to ESP as not tanker or bulker. However, the vessel is some 29 years old. There has been no forward survey planning and the vessel has been laid up for 8 years plus. Can I have your thoughts on this?

Sir, please help me to answer the question. "what is the purpose of Enhanced Survey Programme" (its a question that carries 10 marks in COC 3 written)

The best guide for ESP.

Good post Mr. Rajeev, all is clear and simple. Just one misprint related to minimum thickness calculation scheme where 10% of 40mm should equal to 4mm.

Sir, Can u please explain what are documents and certificate need for dry dock

Dear Capt. Rajeev Jassal, Excellent report. Thanks for sharing info. Regards, Capt Uday Sane

A survey program requires a lot of hard work, careful inspection and a good team work as well. It is a necessary thing for the effective workings of that survey program. Thank you very much for giving us these details here. Surely, this is going to help a lot of people. Keep sharing! Construction damage survey

Thanks for your valuable work captain

When it comes to survey program, people should be very careful while dealing with that. A survey requires a lot of things, information, hard work and many more. It is quite essential for any person to provide the proper and fair results after the surveys. It can help a lot in dealing with situations. Thanks. Construction damage survey

What to do if ESP file is missing on ship?

Thank you for SHARING these information Sir.

can i apply for a deck hand possition at myseatime? please im determine

Great explanation as always

Great article sir....

Thanks a lot Capt Rajeev Jassal. I found your article very interesting and easy to make student understand . Topics details are well thought over & précised, composed. Thanks again.

Dear Capt. Rajeev Jassal, thanks for sharing. May I ask if you've sailed to Nigeria before? If yes, have you sailed to Matrix Energy, Warri, or any Port Oghara, Delta State.

Leave Comment

More things to do on myseatime

MySeaTime Blogs

Learn the difficult concepts of sailing described in a easy and story-telling way. These detailed and well researched articles provides value reading for all ranks.

Seafarers Question Answers

Ask or answer a question on this forum. Knowledge dies if it remains in our head. Share your knowledge by writing answers to the question

MySeaTime Podcast

This podcast on the maritime matters will provide value to the listeners. Short, crisp and full of value. Stay tuned for this section.

Good day sir, very well written as usual, do write on CAS/CAP also when you get time, also please advise who makes the Survey planning document, is it class or owner, and when is it made, at the time of build or before 4th annual survey. TIA