GMDSS batteries provide power to GMDSS equipments in case ship’s main as well as emergency power fail. The requirement of GMDSS batteries is governed by Regulation 13, Chapter 4 of SOLAS.

As per SOLAS, GMDSS batteries should provide power to operate GMDSS for

- 1 hour in case GMDSS has the power from emergency generators

- 6 hours in case GMDSS does not have the power from emergency generators.

- Batteries must be recharged to the required minimum in less than 10 hours.

- The capacity of the batteries must be checked at interval of less than 12 months.

Maintaining the GMDSS batteries in excellent condition is important to have them ready in emergency. There are typically three type of tests/Maintenance done on GMDSS batteries.

- Daily on Load/Off Load test

- Yearly Capacity test

- General Maintenance required on the battery.

1. Daily On Load / Off Load test

On load / off load test is done to ensure that

- GMDSS equipments can have the power from battery. This ensures that all the connections from the battery to the GMDSS equipmemts are intact.

- Battery is able to provide power during operation of the GMDSS equipments. That is when load is put on battery, it does not drain out too quickly.

For the on Load / Off load test, Following procedure should be followed

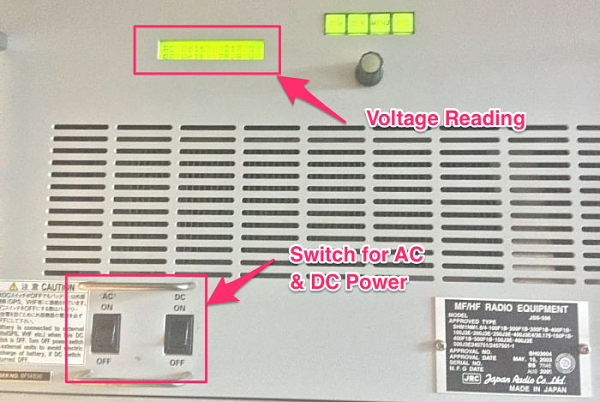

1. First Switch off the AC power to the GMDSS station. The power button is usually under the GMDSS panel or on some ships in the radio room (if you still have one). If you have different AC source for charging the battery, that too need to be switched off. This is because if the battery is on continuous charge, this will not show any drop in voltage which we intend to find out with On Load/Off Load test.

However most of the time, GMDSS power source flow is AC power to batteries to GMDSS equipments. Switching off the AC power automatically ensures batteries are not on continuous charging during test. So after the GMDSS equipments are on battery power, note down the voltage of the batteries.

2. Press the PTT button to transmit on a non-distress and idle R/T frequency. Note down the on-Load voltage while the PTT is pressed.

3. The drop in voltage should not be more than 1.5 volts.

2. Capacity Test

All batteries have a life span. The capacity of a battery can reduce with age. There has to be a way to measure the capacity. And with Capacity test we do exactly that.

We can understand the capacity test with the comparison to a water tank. We do not know how much water it can hold. The one way of measuring its capacity would be filling the water tank to full and then measuring it by draining. Measurement can be with flow meter or with smaller measuring buckets/container.

With capacity test, we measure the capacity of battery by same method. We charge the battery to full and then measure it by discharging. To discharge the battery, we apply a known load to measure its capacity. Capacity of the battery is measured in Ampere hour (Ah). So 200 Ah means the battery can give a current of 200 Ampere for one hour or 20 Amperes for 10 hours and so on.

Before we proceed further, let’s agree on these two staements

- The voltage is not the measure of capacity of the battery.

- A battery 100% full (Fully charged) does not mean that it will or can produce the rated capacity.

Looking at the first statement, if the voltage is not the measure of capacity, what is ? As we already discussed, The measure of capacity of a battery is “how much current it can produce for how many hours”. With capacity test, that is what we aim to measure.

It would be easier to understand the second statement with example of a laptop. A new computer with 100% battery might last for 8 hours . After few years same battery 100% charged would only last 4-5 hours. This is due to the ageing of the battery. With age, battery looses its storage space.

Another analogy to understand the second statement would be the same water tank example. If the capacity of the water tank is 2000 Litres and if it is 100% full, does that mean it contains 2000 litres of liquid. We cannot be sure of that as we do know know what is in the bottom of the tank. There could be number of stones at the bottom. This figure can better explain what we are referring to here

Avoiding Deep Discharge

There is another SOLAS requirement about deep discharge of the battery while performing capacity test. In the simplest of the terms, deep discharge means the least voltage a battery can be brought to. If we discharge the battery below this voltage, the battery can loose its capacity to a level where it cannot be used again. For Nickel based batteries this voltage is 1.0V per cell. So for 24V battery pack (1.2V x 20 Cells), the deep discharge voltage will be 20V. While performing capacity test, we should never allow the battery voltage to go below 20V or 1V/Cell.

Now we all must be knowing this basic physics

Power = Voltage x Current

The GMDSS battery is usually in the range of 200 Ah which is required to give 24V.

We need to test if it still has 200Ah left in it. For this we need to remove the batteries from charging and the existing load (connections to GMDSS station) and attach some known load to it. Usually a rig which consists of number of 100W bulbs in series is attached to the batteries terminals. Say, if 6 bulbs (600W )are attached to the battery, it would draw 25A of current from the battery bank. This is because

600 watts / 24 Volts = 25 Amp

Once the load is attached to the battery bank, we need to measure the voltage and the current across each battery bank terminal. We need to do this at least every hour. This will continue and we shall stop the test only if

1) The one battery cell is failing. That is drop of voltage in one battery cell is different than others. In this case we need to isolate this failing cell and then continue the test.

2) The voltage has reached the deep discharge voltage. SOLAS requires that while performing the capacity test, deep discharge of the battery shall be avoided. We have already discussed what deep discharge is. During the test we need to measure the voltage of each cell. The voltage should not go below 1V in any cell or 20V for the battery pack.

3) The test has performed for sufficient time to show that battery has 100% of its rated capacity. Say it has been 8 hours since the test started. And for 8 hours the current measure was 25A. So the battery has already delivered 200Ah (25A x 8 Hours). This shows that battery’s capacity is still 100%. In this case, this would conclude the test.

If we stop the test because of 3rd point, the battery is fine. If we stop the test because we have come to deep discharge voltage. We need to measure how much Ampere Hour has the battery delivered at this point. If it is less than 80% of its rated capacity, the capacity test has failed.

Charging the battery after capacity test

If the measured capacity is more than 80% of the rated capacity, we can move to next step where we measure the time required to charge the battery. There are two parameters to show the percentage level a battery is charged. These are terminal voltage reading or the specific gravity of the electrolyte. A 24V battery when fully charged would show a voltage of around 25.4V and specific gravity of 1.265. Determining the state of charge with voltage can be tricky as voltage can change with temperature. Specific gravity of electrolyte is considered more accurate way to determine state of charge of battery. So after the capacity test, we need to measure the time a battery takes to charge to 100%. SOLAS require this time to be less than 10 hours.

3. General maintenance required on GMDSS Batteries

The onboard batteries do not need much of maintenance as such. There are two things that need to be checked. First is the electrolyte level and second is the specific gravity of the electrolyte. If you have maintenance free batteries onboard, you do not need to check anything on that except the conditions in which it is stored.

Level of the electrolyte

The level of electrolyte can reduce due to various reasons but it is important that the level is maintained as per the manufacturer’s instructions. If the level is low, the battery cell must only be refilled with distilled water.

Checking specific gravity of the electrolyte

Specific gravity of the electrolyte is considered more accurate measure of state of charge of the battery. Specific gravity must be checked daily and recoded in battery log alonwith voltage. Specific gravity can reduce because of sulfation which causes the charging plates to be deposited with crystals. This causes reduction of holding charge and thus the capacity of the battery is reduced. BCI (Battery Council Internation defines specific gravity of 1.265 as 100% state of charge. 1.225 is considered 75% state of charge. It is still better to refer to manufacturer’s instructions as some manufacturers can go upto specific gravity of 1.280 as the sign of 100% state of charge.

Conclusion

GMDSS batteries are important equipment which ensures that emergency equipments gets power in real emergency. It is thus important to maintain these batteries in an excellent condition. Various tests/checks ensure that GMDSS batteries would provide the required power. Daily on load/off load test ensures that all connections are intact and when on load batteries do not drop voltage too quickly. Annual capacity test measures the capacity of the battery in Ampere hours. We should replace the battery if capacity is less than 80% of the rated capacity. Finally we should daily check the batteries state of charge by measuring the specific gravity and level of electrolyte.

Share this:

About Capt Rajeev Jassal

Capt. Rajeev Jassal has sailed for over 24 years mainly on crude oil, product and chemical tankers. He holds MBA in shipping & Logistics degree from London. He has done extensive research on quantitatively measuring Safety culture onboard and safety climate ashore which he believes is the most important element for safer shipping.

Search Blog

60 Comments

Well....the Annual capacity test is too technical actually. I want to mention one simple annual capacity test procedure which is mentioned in SOLAS itself : SOLAS says - ''One method of checking the capacity of an accumulator battery is to fully discharge and recharge the battery using normal operating current and period(e.g. 10 h). Assessment of the charge condition can be made at any time,but it should be done without significant discharge of the battery when the ship is at sea''. Which says to fully discharge the battery and then recharge the battery again to 100% which must be within 10 hours. Moreover the Annual capacity test procedure mentioned in the blog will be difficult to explain to the external inspectors(the level of cross questioning some inspectors do). A 12 battery consists of 6 cells connected in series , with only 2 terminals(+ve & -ve), how to isolate a cell or even check a cell voltage out of it? Your views / comments on this?

Amit in your comment you have used the terms "fully discharge", "using normal operating current" and "significant discharge of battery". The technicality is in explaining these terms. These are subjective terms and we need to understand these for battery capacity test. Another thing, 10 Hours of capacity for a battery whose actual capacity at same current is 20 hours cannot be considered good. We need to discard this battery even if it satisfies the SOLAS requirement for capacity required.

In above article isolation is for Nickel cadmium (Alkaline battery). where each cell are connected in series. In case of Lead acid battery as cells are internally connected this is not applicable...even if one cell out of 6 is defective ..we need to replace full battery. In case of alkaline battery we can replace each battery separately..With isolation we can equally discharge each cell before putting in charge..

Thank you for clarifying this further..

On board ship generally 12 cells, each of 2.0v (Alkaline) are used. so when carrying battery capacity test both the cables -ve and +ve be disconnected from battery bank. Now connect the known resistance battery test set and read the readings on battery health meter.

Thank you for this clarification..

It is not Alkaline cell, it is lead acid cell. Alkaline cell max voltage is 1.5V. So, it will be having more than 12 cell, if it is Alkaline cell.

Good information

Glad you liked it Sudhakar

Very useful informations, Just, what should i state in gmdss log regarding capacity test? how should i wrote?

Usually at the beginning pages of GMDSS log it would be stated how each entry is to be made. It can be as simple as "Annual capacity test of GMDSS batteries conducted". This need to be supported with a test report with all the details of voltage and currents measured during the test.

Thanks for useful informations.

Nice and informative article. Helped me a lot

Glad to hear that Ivan

Thanks Capt Rajiv..Very nicely explained.

A comment from an ETO as knowledgeable as you means a lot. Thanks.

Can I switch off al GMDSS AT PORT?

Yes, GMDSS can be switched off at Port. On Tankers, it is must to switch off GMDSS transmitter at port..

it is very useful information for me

Glad you found it useful Yogi..

Very good information..nicely explained..

Glad you liked it Mayank..

Thanks for the information sir, How about the procedure of renewal of General and GMDSS batteries onboard ship? Can you send it to my email . Much appreciated sir thanks.

A maintenance free battery need to be changed before the expiry date. Other batteries need to be changed when the cells are damaged, that is when it does not hold the charge. Is there any other thing you are looking for in procedure for changing the batteries ?

Is the any weekly cheks for batteries?

If we are checking the specific gravity of the cells daily then there is no other thing we need to check every week.

Very useful article ! I would be grateful, if you could tell me what the source of this information was: "3. The drop in voltage should not be more than 1.5 volts.", "If it is less than 80% of its rated capacity, the capacity test has failed." ?

IMO COMSAR/Circ 32 have some of this similar information Dmitrii..

Thanks for your information sir, is there any recharging process during normal operating( means using by main or emergency power sources). If have, How frequently charge and how long for new maintenance free battery.

Usefull info! I have one question, is there any requirement for keeping separate battery log or it is just enough to keep all records (on/off load tests, services) in the GMDSS log book? Regards

Both ways works fine provided we record all the information..

How do we order new batteries for GMDSS

By mentioning the Capacity in Amp Hour number of battery banks required and number of cells in each battery bank..

In your first drawing the setup for a volt meter is wrong. This is a amp test. And very bad for the meter.

Sir, just checked IMO/COMSAR Circ. 32, i think no where it mentions anything regarding "drop in voltage by 1.5 V"...kindly advise

One more good article.

Is it really required to perform radio DSC self-test whilst alongside in port on tankers such as LPG, LNG?

Useful article. Thank you

Dear Cpt. Rajeev, you're doing really a great job, pls keep going ! When time permits, it would be also nice if we can have some new subject regarding correct entries into the GMDSS log book, i.e. it becomes already quite often practice whenever vetting inspector writing such observation as : ''1) All entries have been made by 2/Off only and no any hand over of radio watch has been recorded into GMDSS Log'' density of GMDSS battery(if applicable type) liquid was not recorded while daily/weekly tests'' etc. Thank you

Dear Cpt. Rajeev, you blog is the most useful thing i've ever find regarding my carrer developing. Thank you for the great job. I have one question regarding this topic. According ot STCW requirement if we have ''maintenance-free'' batteries on board we should perform ''suitable load test'' weekly. As i understood it's something different that daily and capacity test because they are also included to requirements together with this weekly suitable load test. Could you advise?

Thanks a lot for another great information. This website has been my gateway to information.

Thanks for this article. Please could you advise with the links of sourse of this information. Especially regarding requirements to perform on/off test daily and procedure as such. I will be appreciate for your assistance with providing this information.

Informative article,Ty fr info.,

Sir , Is it specifically mentioned somewhere that the drop in v should not be more than 1.5 V during on / off load test?

who is actually responsible for maintenance of GMDSS Batteries.... designated deck off for operating GMDSS in distress or electrical off or...??? under which law / rule???. Reply sure sir...it is a question on debate nowadays???. A gmdss goc holder is just an operator with no experience of electrical field. Many company's PMS battery maintenance job is included in El.Off job list or 2nd engr. Please guide on this with certain proof and clearification.

ETO

bull shit

Dear Capt Rajeev, Good day, thanks a lot for your valuable post. Can you kindly advise any reference in any Convention/Circular about on load / off load battery test. Thank you.

Nice explanation.

Sir, can you please let me know the annual GMDSS battery capacity test requirements for newly installed battery ? Is it okay if 1st annual capacity test is done within 12 months after installation of new battery ?

I have one question after i switch AC power to batteries , my gmdss equipment should go on DC power? Im doing a daily test of gmdss batteries and when i switch off ac breaker i think only mf/hf goes on load to battery, other equipment like sat c still has green lamp for AC , should for all equipment be indicated they are on DC power once on battery? Is there any requirement that entire gmdss equipment should be put on load for daily test of battery or only mf/hf can be put on load and battery can still be checked ?) Thanks

I have a question, do batteries (in emergency generator, battery and gen. Use batteries) needs to be covered as per SOLAS (PSC told that this should be covered as per solas but he failed to cite the SOLAS regulation)? If yes could someone help me cite the article. Please. Thank you.

A giant assistance to all seafarers.

Hi, While the whole article is deeply covered about the batteries......it lacks the very important and most often forms the part of argument is about........solas rules for carrying for carrying out gmdss annual load test. Vessel should be underway, an anchor or while the vessel at Port. You should have started with these rules in start of the topic. This would have nailed the article. Thanks for good articale though. Vijay

Nice one...

Actually what is the rule while the vsl at anchor waiting for pilot or berth? Do we need to log down daily/weekly tests? As the vessel is only keeping a listening watch on VHF?

Leave Comment

More things to do on myseatime

MySeaTime Blogs

Learn the difficult concepts of sailing described in a easy and story-telling way. These detailed and well researched articles provides value reading for all ranks.

Seafarers Question Answers

Ask or answer a question on this forum. Knowledge dies if it remains in our head. Share your knowledge by writing answers to the question

MySeaTime Podcast

This podcast on the maritime matters will provide value to the listeners. Short, crisp and full of value. Stay tuned for this section.

Very nice article

Thanks Buddy...

Is there any rule from SOLAS stating that, while vsl stay at port during cargo operation especially on tanker vessels, you cannot make test of GMDSS equipment, if there is what regulation? Thanks mate.

SOLAS lists the rules not procedures. For example SOLAS will not lists precautions during tank cleaning etc. This information however will be present in ISGOTT. Also in ship shore checklist, we need to keep the antenna earthed which is only possible if we do not transmit.