Shipping is changing drastically and not all changes are liked by shipowners, ship managers, and seafarers.

But if there was one change that is being welcomed by all is this…

Shipping industry now takes every personal injury or death very seriously.

For tanker operators, the oil Majors even require a death onboard any of their vessels to be reported to them.

We have to consider this change as a welcome change.

The KPI for Personal injuries and deaths need to be set to zero, an absolute zero.

But one area where we keep hearing about the loss of life or injuries for that related to embarking and disembarking of pilots.

We need to bring these to zero as well.

But that won’t happen just by thinking about it.

Pilot embarkation & disembarkation is a very routine but risky operation.

We keep hearing the tragic news of the death of pilots while embarking and disembarking from the ships.

All of these accidents are avoidable.

So what we, seafarers can do to avoid these accidents?

Well, we can ensure that the boarding arrangements are adequate and safe for pilot embarkation and disembarkation.

Let us discuss how it is done.

Pilot ladder requirement

The principle requirement for the pilot ladders is governed by Regulation 23, chapter V of the SOLAS.

There are few other references that talk about the construction of pilot ladders.

But if we need to bring the accidents due to pilot ladders to zero, we need to address three things.

- We need to ensure that pilot ladders onboard are made of the required material and as per the guidelines

- We need to make sure that the pilot ladders are maintained properly

- We need to make sure that the pilot ladders are used or rigged correctly

Let us understand each of these points in more detail.

Requirements for the construction

The first requirement is that the pilot ladder need to be certified by the manufacturer.

This means that the pilot ladder now no more can be made by the ship staff.

These need to be supplied and the manufacturer need to certify these to be complying with the SOLAS.

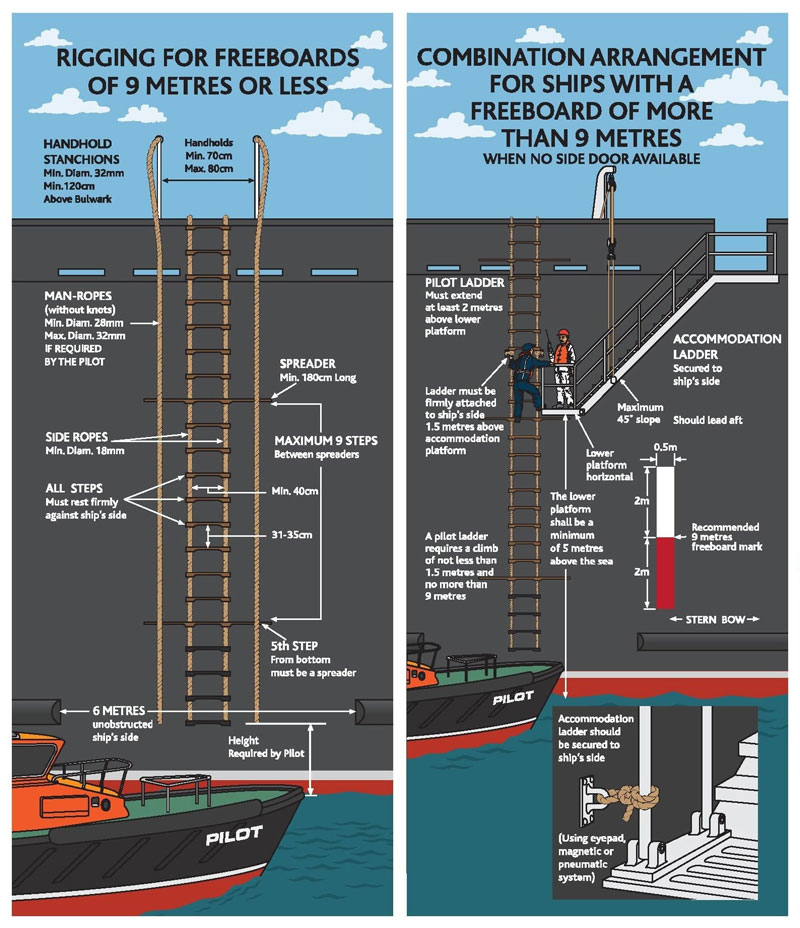

Then there are requirements for

- The step of the pilot ladder

- Location of the Spreader

- Ropes used in the making of the pilot ladder

- Side ropes

- The distance between each step

All these requirements are clearly defined in the IMPAHQ poster that all the vessels are required to have on the bridge.

Requirements for the maintenance of Pilot ladders

As per SOLAS ch V/Reg 23, all pilot ladders used for pilot transfer shall be clearly identified with a tag or other permanent marking.

The marking is required for the identification of the pilot ladder.

The marking could be by attaching a piece of canvas and stenciling the number on it.

But the best way of marking is by use of a scafftag.

Other SOLAS requirement is that the appliances shall be kept clean, properly maintained and regularly inspected.

The inspection of pilot ladders needs to be done as per the PMS routine of the company.

But what do we mean by properly maintained and what can we do to ensure that pilot ladder is appropriate for the use?

1. Ropes

The first thing that needs to be checked is the condition of ropes.

Most of the pilot ladder incident that occurs is usually because of the parting of either the ladder rope or the side ropes.

Why do these rope part and what can be done to avoid this?

Use of Manila rope is one of the requirements for pilot ladders.

There is a reason for this requirement.

Manila rope has an absorbing quality which ensures that the rope is always non-slippery.

That makes it the first choice for the purposes like stage rigging and use in the making of pilot ladders.

But this quality is also a concern when it comes to absorbing seawater and sunlight which may harden it or rot it over a longer period of exposure.

This can sometimes trick a seaman.

A manila rope which might look in excellent condition but which has been exposed to sunlight, sea water or even chemicals might have lost its internal strength.

Negligence of the seafarers to inspect and discard any obvious damaged rope and pilot ladder is one thing.

But a bad rope with the excellent visual condition can also be the cause of pilot ladder ropes giving way.

The best way to avoid degrading of the pilot ladder rope is to minimize its exposure to seawater, sunlight, and chemicals by securing it nicely when not required.

However considering that the visual inspection of manila ropes used in the pilot ladder can sometimes give a false indication of its condition & strength, I am personally of the opinion that pilot ladder should be changed with a new one after a fixed interval of time, irrespective of its condition.

2. Steps

At an interval required as per the PMS of the ship, the pilot ladder should be opened up and laid on the deck.

The close inspection of each of the pilot ladder steps must be made to identify any steps that show the early signs of cracking.

Apart from that, each step must be secured firmly and should be straight and not inclined towards any side.

Requirements for use of pilot ladders

A good and well-maintained equipment is good as long as it is used correctly.

The pilot ladder needs to be rigged correctly for it to be considered safe.

And the first thing that needs to be considered is the location of the pilot ladder deployment area.

As per SOLAS, the area needs to be

- clear of possible discharges of the ship (for example scupper plus).

- within the parallel body length of the ship and as far as practicable, within the midship half length of the ship

- Each step must rest firmly against the ship’s side.

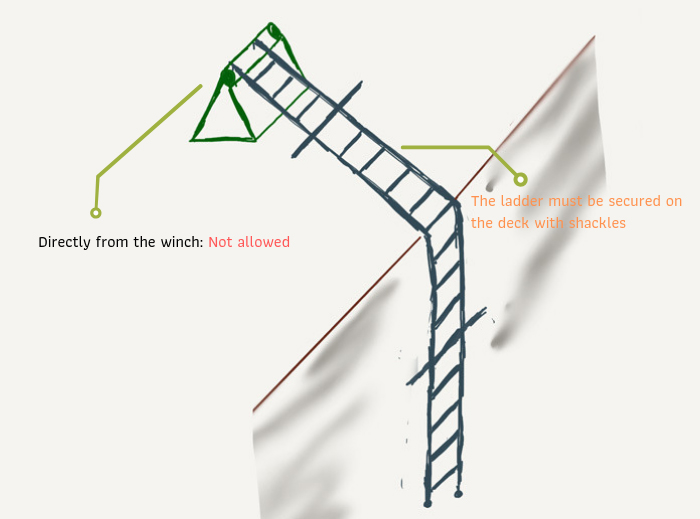

The second consideration is how the pilot ladder is secured to the ship.

If the pilot ladder is stored on a winch, the pilot ladder must not be hanging from the winch. This must be secured on the deck with the shackles.

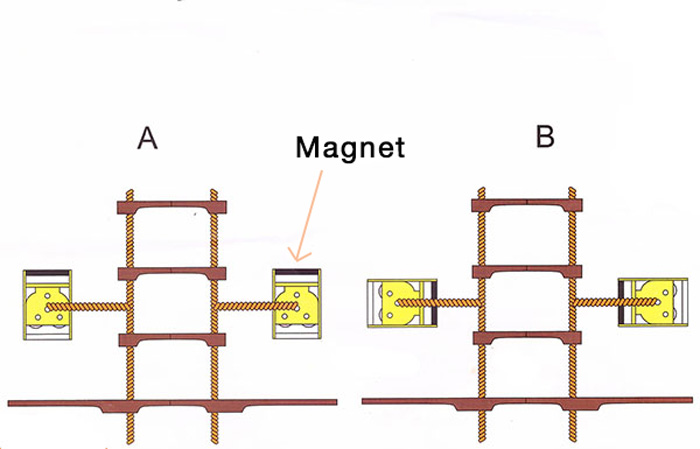

When the freeboard of the ship is more than 9 meters, we are required to use the combination arrangement for pilot embarking.

In this case, the pilot ladder and man-ropes need to be secured at a point about 1.5 meters above the bottom platform of the accommodation ladder.

This is usually achieved by attaching portable magnets the ship’s side and securing the pilot ladder to these magnets.

There are a few other points that we need to be aware of while securing the pilot ladder.

If the pilot ladder is secured at its ends (the thimble at the end of the pilot ladder rope), it can be secured with the appropriate shackles.

However if Pilot ladder needs to be secured at the intermediate length, it need to be secured with rolling hitch knot.

Use of shackles for securing the ladder at intermediate length is a big no-no and dangerous.

Use of shackles for securing the ladder at intermediate length is a big no-no and dangerous.

The crew must check that the pilot ladder step is not resting on the fish plate. This can snap down once someone puts his weight on the pilot ladder.

In fact, any of the pilot ladder steps must not be resting on any of the ship’s structure.

The pilot would be lucky if he gets warning for inappropriate securing of the pilot ladder after climbing for a few steps.

There have been incidents where the pilot ladder step snapped down and the pilot fell from a considerable height.

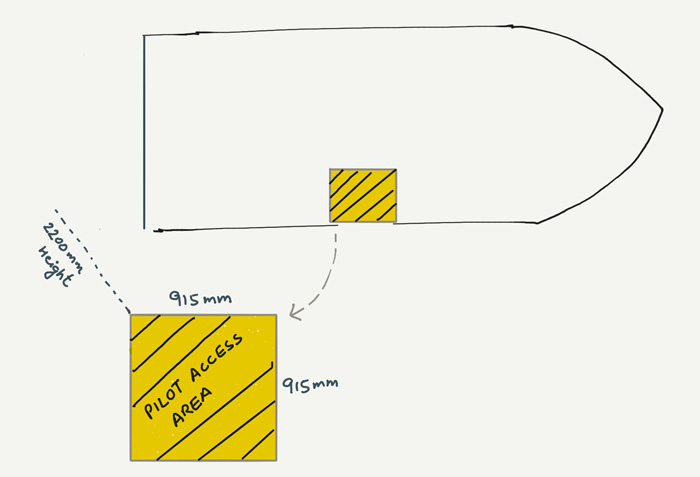

Access to deck

Once the pilot boards the ship the area where he would keep his first few steps need to be clear.

IMO Resolution A. 1045(27) gives the dimension of this area that needs to be kept clear of any obstructions.

The dimensions of the are that need to be kept clear are

- 915mm in length measured longitudinally along ship’s length

- 915mm in width measured inward from the ship’s side

- 2200mm in height measured from the main deck

As a good practice this area is marked on the deck on each side of the ship.

Conclusion

In layman’s mind, the embarking and disembarking of pilot would be a routine and non-risky task.

But the number of accidents during this operation points otherwise.

All these incidents can be avoided by having a set of best practices related to use of pilot ladders.

Pilot ladders onboard should be of correct specification and ship staff should have certificates for the pilot ladders onboard.

Pilot ladders should be secured when not in use.

Exposure to sunlight and seawater should be minimised as far as possible. On longer voyages, the pilot ladder should be kept under shelter such as in deck store.

The condition of ladder ropes, steps as well as other fittings should be checked at least monthly and before use.

Share this:

About Capt Rajeev Jassal

Capt. Rajeev Jassal has sailed for over 24 years mainly on crude oil, product and chemical tankers. He holds MBA in shipping & Logistics degree from London. He has done extensive research on quantitatively measuring Safety culture onboard and safety climate ashore which he believes is the most important element for safer shipping.

Search Blog

2 Comments

The following statement in the article is factually incorrect...'Pilot ladder needs to be secured with appropriate shackles to a strong point on the deck. Use of ropes to secure the pilot ladder is a big no-no.' Ropes should ALWAYS be used shackles should NEVER be used. This information in incorrect and highly dangerous. I am a pilot and have been for 19 years. We struggle to improve safety when such incorrect information is shared.

Leave Comment

More things to do on myseatime

MySeaTime Blogs

Learn the difficult concepts of sailing described in a easy and story-telling way. These detailed and well researched articles provides value reading for all ranks.

Seafarers Question Answers

Ask or answer a question on this forum. Knowledge dies if it remains in our head. Share your knowledge by writing answers to the question

MySeaTime Podcast

This podcast on the maritime matters will provide value to the listeners. Short, crisp and full of value. Stay tuned for this section.

is there any certificate requirement also for embarkation ladder of life raft?